Automobile bumper scan case

One well-known domestic automobile manufacturers need to reverse design of the bumper, the form of independent research and development of dynamic three-dimensional picture type 3 d scanner - HL 3 ds + 3 d scanning was carried out on the car bumper, access to the high precision of 3 d data, improve the efficiency of secondary development of auto insurance, save the cost, shorten the development cycle of new products.

Practical problems

1, simply use the traditional methods (such as fixture, fixture, three coordinates, etc.) to measure the car bumper, very tedious, time-consuming, and not to the shape of the car bumper measure rapidly and accurately, test.

2, car insurance, there are many surface and card buckle area, and volume is larger in the bumper prone to deformation, the general 3 d scanner is difficult to quickly and accurately obtain three-dimensional digital model of car bumper.

CO3D solutions

The customer wants to make further improvement on the car insurance rod produced, save production cost and improve the product qualification rate. So shape dynamic 3 d engineer provides professional solutions: use photo type 3 d scanner - HL 3 ds + (quick car bumper and high precision of 3 d data) + reverse engineering software Geomagic Studio (the car bumper point cloud data into a triangular mesh surface) to assist the company to undertake secondary design of car insurance.

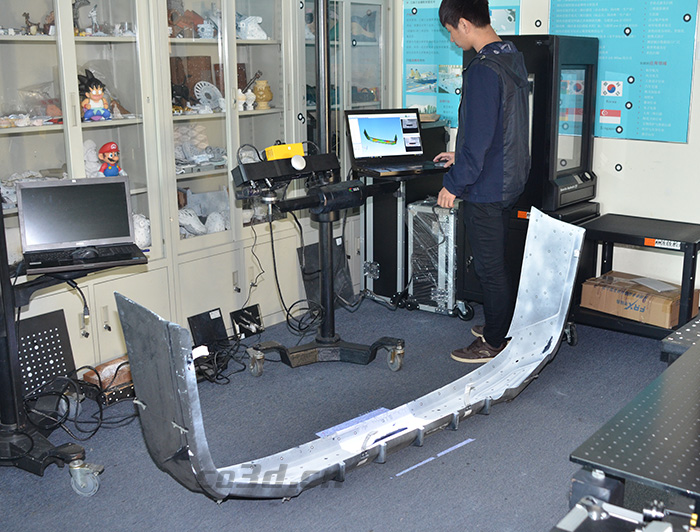

Car bumpers

Car bumpers scanning scene

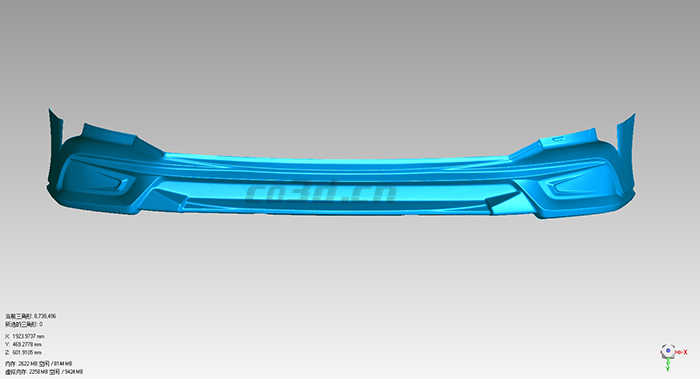

Auto bumper STL data graph

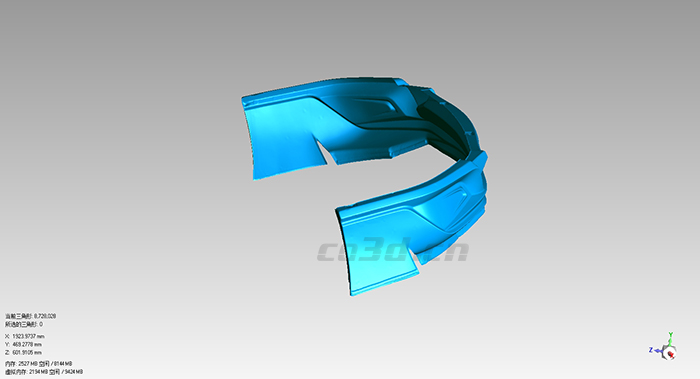

Auto bumper STL data graph

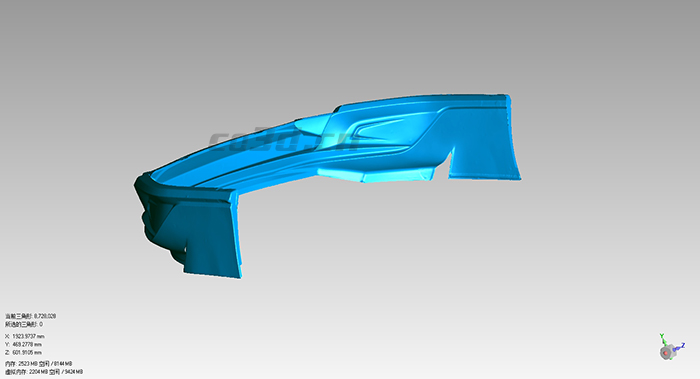

Auto bumper STL data graph