Off-road vehicle roof three-dimensional scanning detection

Nowadays, travel is carried out by car, which is convenient and saves time and effort. The car has become a transportation tool widely used in various fields of social and economic life. With continuous improvement, the requirements for all aspects of the automobile are becoming more and more strict. It is not simply a tool that can travel, but also promotes the development of new automotive technologies. It is not only the development of internal software systems, but also the evolution of the shape of the car. In a period of time, we are constantly developing new shapes. It is a development of automotive aesthetics. It has become a variety of types and specifications. A car company customer needs to scan and test the car roof to obtain data, which can be used for R&D design comparison and transformation.

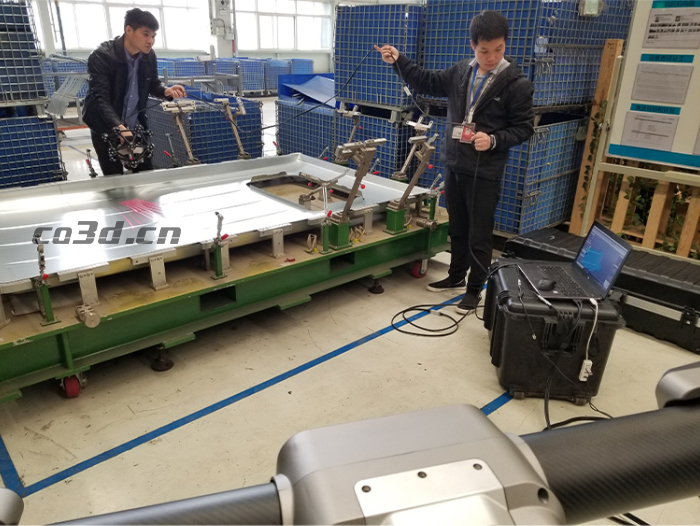

Off-road vehicle frame real shot diagram

Practical problems

1. The car roof has a complex curved surface and a large body. The customer needs to quickly scan the object, quickly output data, and requires high precision.

2, using a general traditional scanner, the scanning range is small, time-consuming, data processing for a long time, and the accuracy does not meet the requirements.

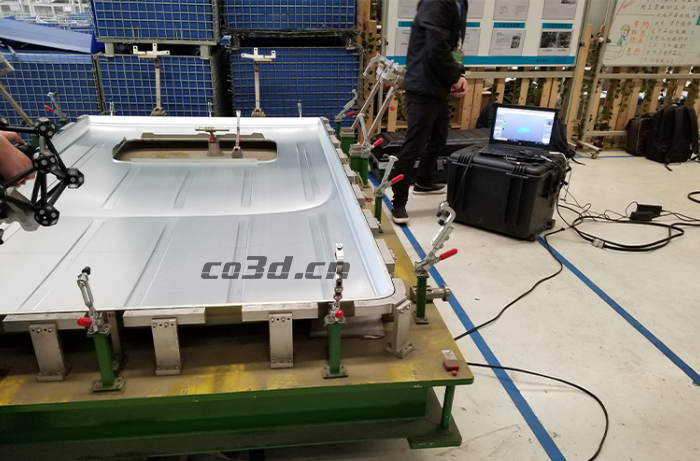

Roof scene scan

Co3d solutions

After understanding the customer's requirements, Hualang 3D engineers decided to use the HL-scan 3D scanning system to display the data in real time when demonstrating the scanned workpiece to the customer, and without having to process the surface of the object, the scanning range is large, and the large workpiece is scanned. Very suitable, short time. It can also be scanned with the robot arm to reduce manual intervention scanning, save manpower and improve work efficiency. Moreover, the scanning accuracy is high, and the scanned data is processed to meet the requirements of the customer, and the customer is very satisfied with this.

Roof scene scan

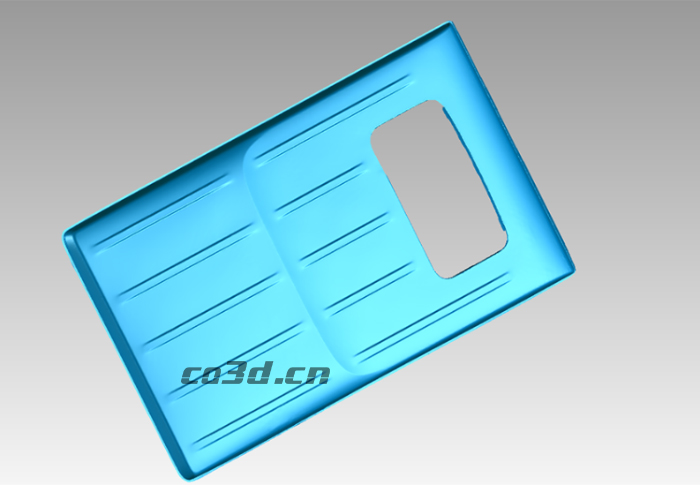

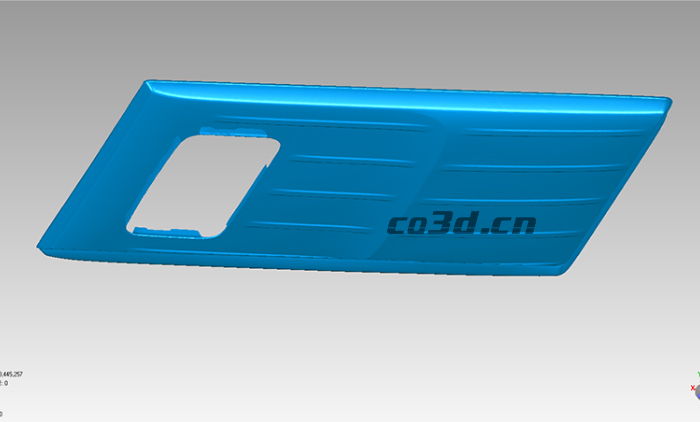

Roof STL data map

Roof STL data map

Roof STL data map