3D scanning of automotive stampings

Auto stampings are metal stampings that make up automotive parts. There are many kinds of automobile stamping parts, and all kinds of them are manufactured according to the performance requirements of auto parts. In the production process, the process is suitable for industrial multi-variety and mass production. The relationship between cold stamping materials and automobile stamping parts production is very close. The quality of the materials not only determines the performance of the products, but also directly affects the process design of the automotive stamping parts process, affecting the quality, cost, service life and production organization of the products. Rational selection of materials is an important and complex task. Manufacturers want to test stamping parts in production, ensure product quality, and improve production and material saving.

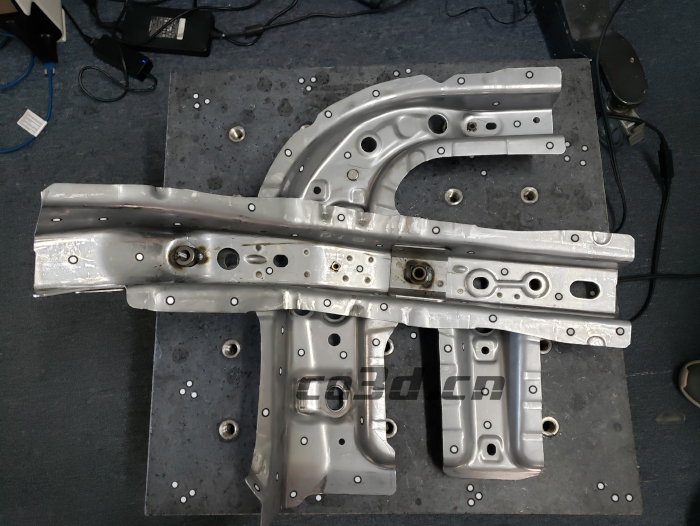

Auto stamping parts

Practical problems

The overall structure of the automobile stamping parts that the customer needs to detect is complicated, the shape is irregular, the unevenness is uneven, the groove is deep, and the whole workpiece is provided with holes, which brings certain difficulty to the scanning work.

With the conventional 3D scanner, it is difficult to fully capture the workpiece with complex structure, and it is impossible to scan and obtain accurate data for more details.

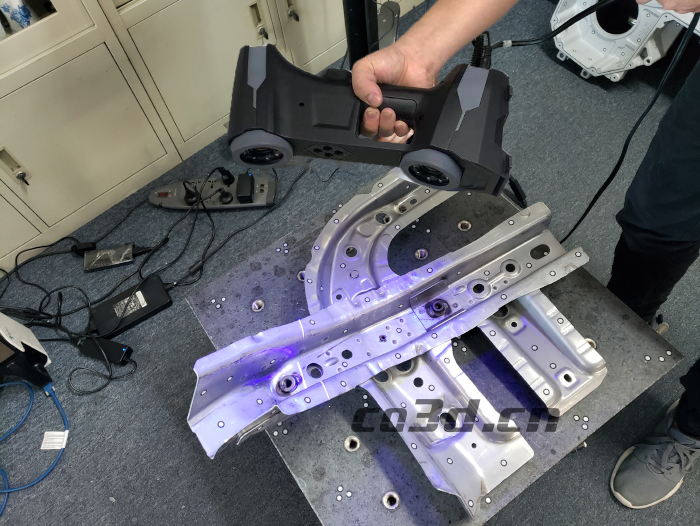

Auto stamping parts on-site scanning

Co3d solutions

After understanding the details of the workpiece, the HOLON760 handheld 3D scanner is light, flexible and easy to carry to adapt to various scenes and different workpiece structures. It is easy to solve with high precision requirements, and the measurement accuracy of single machine is up to 0.02. Fast and efficient, using 7 sets of crossed laser lines plus an additional laser line for a total of 15 laser lines, can also be switched to a single laser scanning mode, suitable for scanning deep holes and dead angles, accurate scanning details. Easily scan automotive stampings from different angles and positions, and output data in real time. The overall scanning speed is very fast. High-precision 3D scan data is imported into the inspection software for inspection and analysis. The analysis report is easy to understand and the details are processed. Very satisfied, can intuitively understand the quality problems of the product data, the scanning effect is very good.

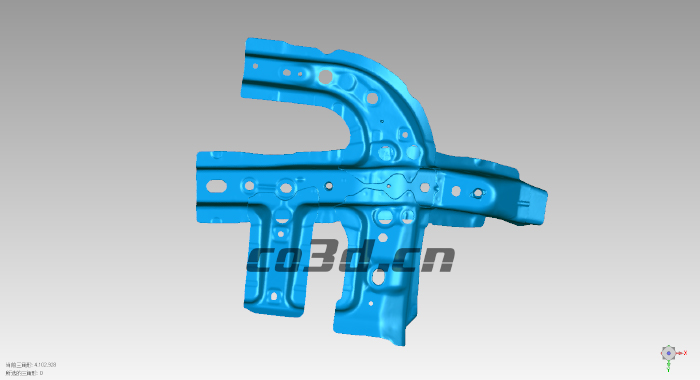

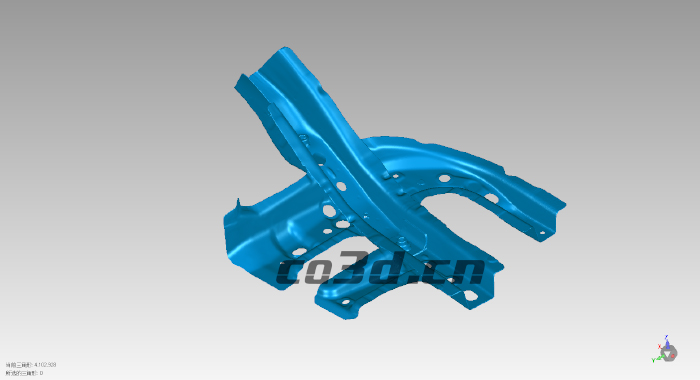

Automotive stamping parts STL data chart

Automotive stamping parts STL data chart