3D scanning of automotive anti-roll bars

The function of the car anti-roll bar is to reduce the roll of the vehicle when cornering and improve ride comfort. From small cars to heavy trucks, the front overhang is mostly equipped with stabilizer bars. Due to the need to avoid other surrounding parts when designing, stabilizer bars come in a variety of forms, but they are basically the shape of flexor arm and torsion bar. In addition, the cross-section of the material has two forms: solid and hollow, and the use of hollow materials that are beneficial to lightweight is increasing, and the demand and application volume of the automotive anti-roll bar market are also increasing correspondingly.

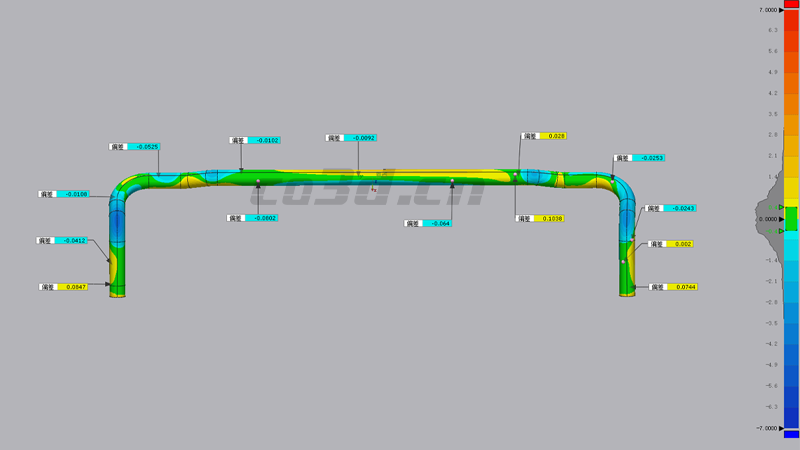

A well-known auto parts manufacturer at home and abroad, in order to measure the three-dimensional data of the anti-roll bar, the obtained three-dimensional data is compared with the original data for comparison, and a very intuitive three-dimensional detection chromatogram can be obtained. According to the comparison report, the overall deviation between the actual anti-roll bar and the original design drawings can be clearly seen, and the error of the workpiece can be clearly known.

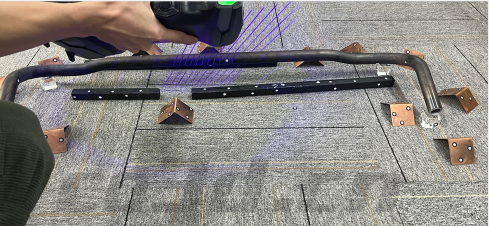

Actual drawing of car anti-roll bar

Actual drawing of car anti-roll bar

面临问题| Practical problems

The symmetrical center of the anti-roll bar of the car is extended to the two pairs of sides to detect deviations. Detect wear and deformation of the joint between the anti-roll bar flexion arm and the car. The car anti-roll bar is rounded, and the surface cannot be pasted with too many points, which will affect the surface characteristics and cause detection deviations. Traditional detection methods are time-consuming and difficult to detect, and detection deviations will occur.

3D scanning site view of automotive anti-roll bars

3D scanning site view of automotive anti-roll bars

解决方案| solutions

1. Paste the scanning around the anti-roll bar of the car, extend the scanning from the central axis to both sides, and automatically stitch the point cloud data to scan the surface features of the anti-roll bar.

2. Hualang 3D technology engineer uses handheld 3D scanner A22 scanning to quickly obtain three-dimensional data of auto parts anti-roll bar, improve work efficiency, handheld convenient and flexible, light and easy to carry, sensitive and convenient operation process, 22 laser wire harnesses, fast scanning speed, multi-mode switching scanning accuracy, strong stability, a wide range of applications.

3. Import three-dimensional software for data comparison and detection processing, successfully solve customer problems, and achieve the accuracy and effect of customer needs. It accelerates the efficiency of customer production and processing, and saves a lot of time and cost of manual inspection.

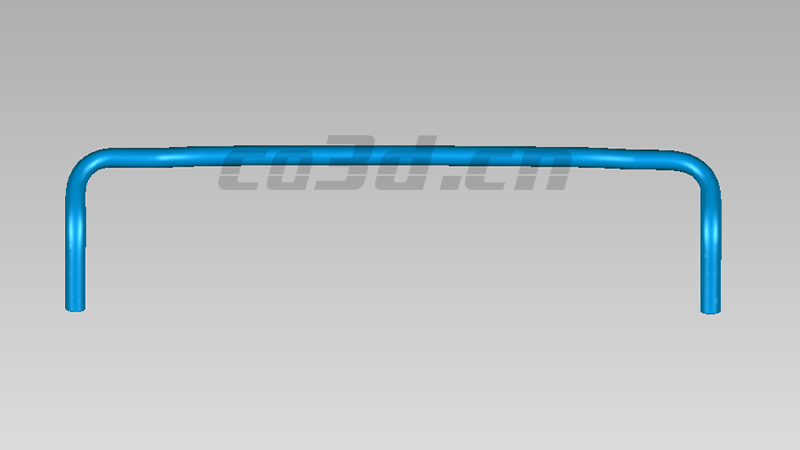

Automotive anti-roll bar 3D scan STL data diagram

Comparative detection and analysis diagram of automobile anti-roll bar