Tricycles are commonly used lightweight transportation tools in today's society, which can play a significant role in carrying people and transporting goods. The safety of a tricycle relies entirely on its frame, and as an important component of an electric tricycle, quality control becomes of utmost importance.

Practical problems

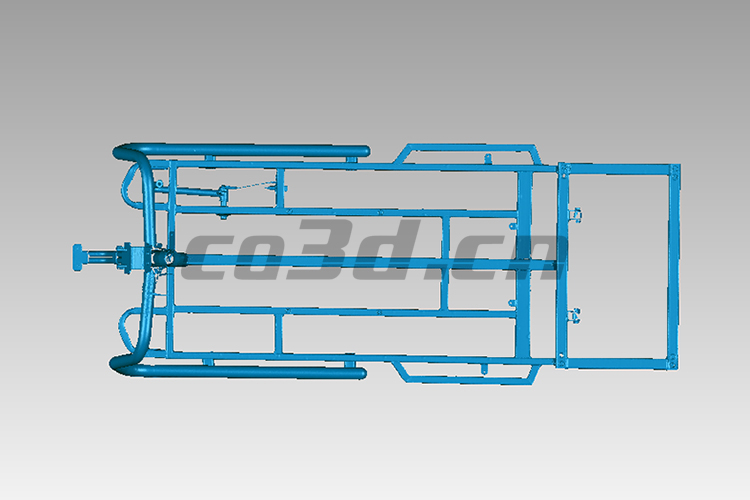

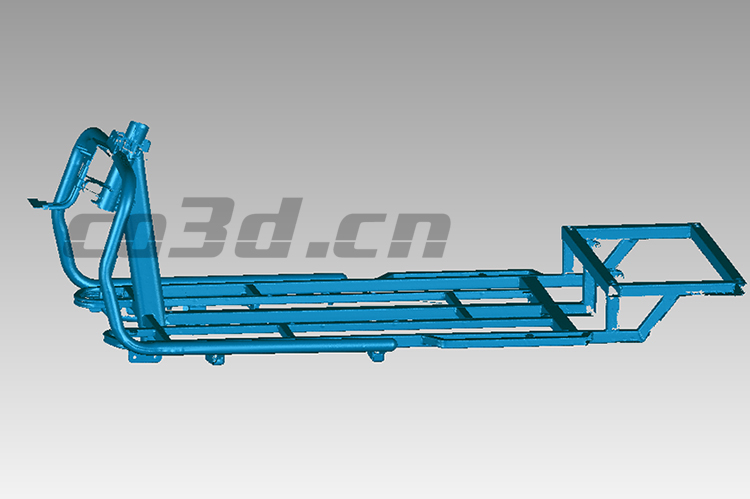

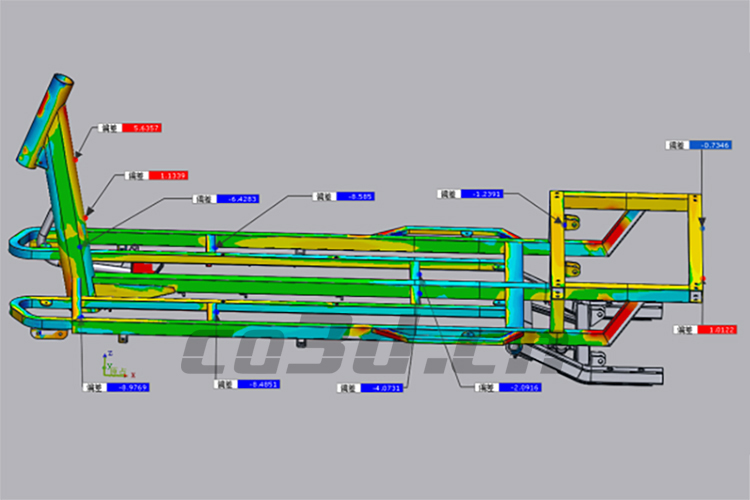

The customer requires a 3D scanner to scan high-precision complete data with high efficiency, detect actual machining errors, and ensure safe driving in the later stage. The three wheeled frame is an alloy tube frame structure with a large curvature, making it difficult to use traditional measurement methods and unable to quickly and accurately obtain the three-dimensional model data of the electric vehicle frame.

Co3d solution

Using 14 laser lines+7 fine modes+1 deep hole mode, the scanning speed is 1350000 measurements per second, which can quickly complete the scanning work; With an accuracy of up to 0.02mm, dual industrial cameras, automatic stitching technology for marker points, and independently developed scanning software, it has high scanning accuracy and work efficiency. By comparing with the original data, obtain a simple and understandable 3D detection report,