3d scan of aircraft wheel

As a part of aircraft tires, aircraft wheels bear the effects of high speed, high load, and high internal pressure. They play an extremely important role in the safe take-off and landing and taxiing of the aircraft, requiring high requirements and requiring regular inspection and maintenance. Therefore, the customer wants to obtain the digital model of the wheel, and the three-dimensional scanning technology can realize the data acquisition and retain the data for later damage repair.

Site scan

Practical problems

The surface structure of the aircraft hub is complex, with many holes and different sizes. Therefore, when using ordinary 3D scanners, there will be difficulties in the scanning process and the scanning process is not convenient, which makes it impossible to obtain accurate data. It is necessary to use more convenient and flexible three-dimensional scanning equipment for scanning work to meet customer requirements for high accuracy, fast scanning speed and complete scanning data.

Site scan

Co3d solution

The proposed solution is to use the Hualang handheld 3D scanner HOLON751. This device has fast scanning speed and high accuracy, and it has scanning deep hole and fine scanning modes, which can solve the scanning of hub holes and small parts. First, mark points are pasted on the surface of the hub for positioning and splicing. Use a handheld 3D scanner to scan quickly and collect high-precision data. Import the acquired data into the reverse engineering software for reverse modeling. In the later stage, the damage location can be quickly obtained through the comparison of 3D data and digital and analog, and the problem can be found and repaired, providing professional technical solutions.

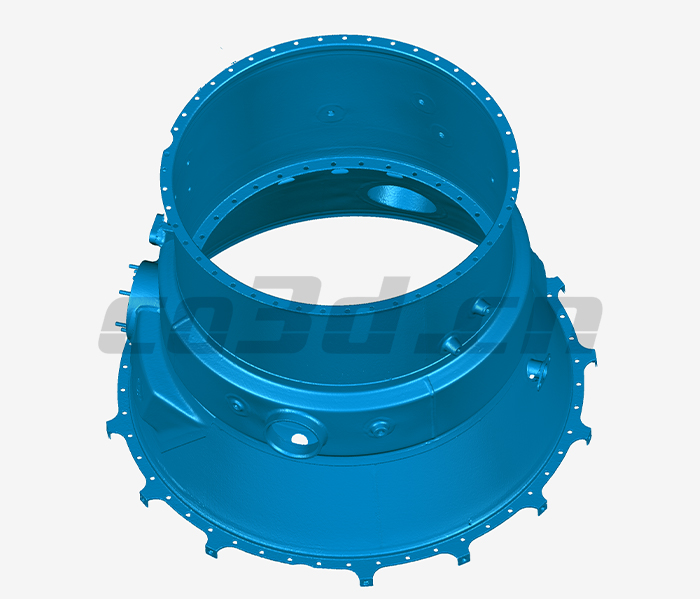

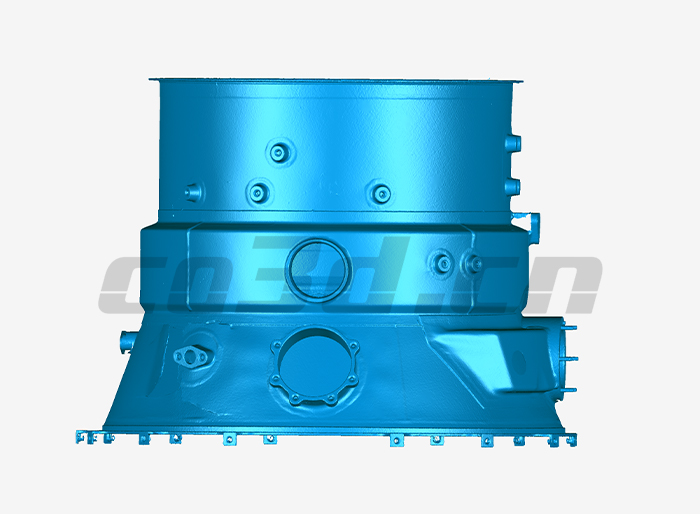

Scan STL data graph

Scan STL data graph