Three dimensional detection of large turbine blades

The thickness and curvature of large turbine blades are large, and there is no obvious solidification sequence. So it is very necessary to improve the casting technology and improve the quality of the blade.

Practical problems

1 large turbine blade surface curvature change, distortion, resulting in the amount of data acquired is not complete, can not be accurate detection of turbine blades.

2 the traditional measurement method, which takes a long time, and is unable to carry on the comprehensive inspection to the turbine blade.

CO3D solutions

Case profile:

A large domestic turbine production enterprises, in order to solve the problem of improving the quality of blade casting, decide on the turbine blade mould were detected using Huaguang 3D photogrammetry technology, anti deformation measures in large curvature section.

Scanning device:

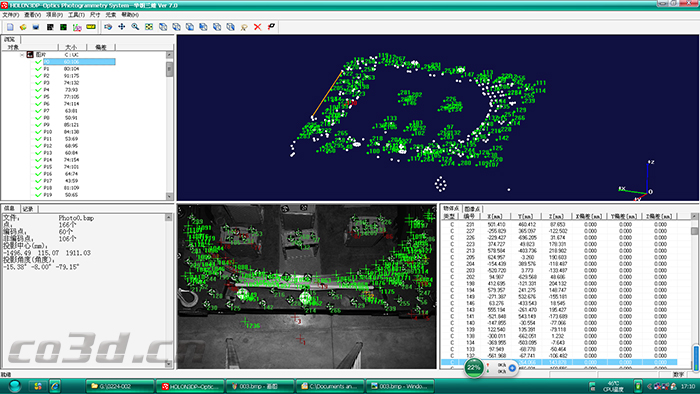

HL-3DP 3D Photogrammetry

Product features:

To quickly calculate the workpiece surface encoding points and mark points, accurate 3D coordinates.

According to the super - 3D measurement of large workpiece, the control precision of the whole workpiece.

Adopt alloy target rod, higher stability.

The physical diagram of large hydraulic turbine blades

Turbine blade measurement site

Three dimensional measurement data of turbine blade