CNC hydraulic die forging hammer three-dimensional inspection

In today's world's largest forging hammer production base, three-dimensional inspection of forging CNC hammer is required. For the forging CNC hammer produced by the company, it cannot be properly installed and matched. Huaguang 3D provides solutions for the enterprise.

Practical problems

1. Forging CNC hammer body is not easy to detect, it is necessary to measure the distance between the joint surface and the lower joint surface on the body and whether the angle of the track surface matches the hammer.

2. The customer needs to quickly scan the hammer head and the fuselage track of the assembly, and the scanning data re.

Co3d solutions

Forging CNC hammer testing, due to its large size and cumbersome, the local contour requires very high precision. It is measured by traditional detection methods. Many sizes and shape features cannot be effectively measured, which is prone to secondary error and affects the installation efficiency of the product. . In order to abandon the traditional testing methods, the company uses industrial three-dimensional scanners to test the quality of the forged CNC hammers and develop a reasonable design plan. Huaguang technical engineer proposed a solution: using large-format 3D scanner α7000 to carry out 3D data acquisition on the body and hammerhead, and obtained 3D inspection and analysis report, which provides an effective installation solution for the production of forging CNC hammer.

Scanning equipment:

3D scanner α7000

Features:

1. Carbon fiber military engineering material: high stability, strong thermal shock resistance, small thermal deformation coefficient, higher scanning accuracy and stronger stability

2, 13-step code calibration technology: eliminate lens error

3. Extrapolation multi-frequency phase shift: uniform fringe projection

4, compatible photogrammetry system: higher precision

5, granite calibration source

6, patent design: eliminate the problem of multi-angle scanning stitching

7, the cumulative scanning accuracy is very high, a single machine can complete the workpiece scanning about 4m

CNC hydraulic die forging hammer site map

CNC hydraulic die forging hammer site map

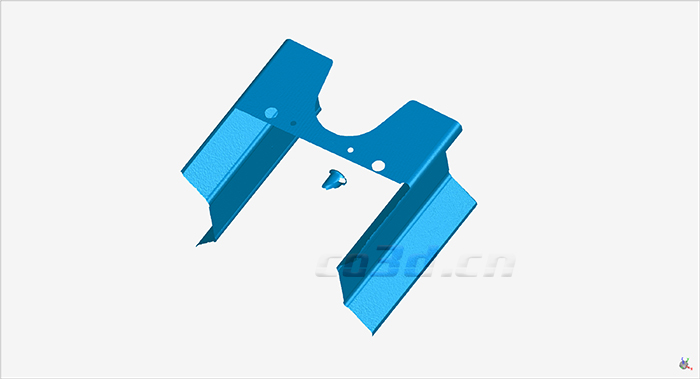

CNC hydraulic die forging hammer scanning STL data

CNC hydraulic die hammer scanning

CNC hydraulic die hammer scanning STL diagram

CNC hydraulic die hammer scanning STL diagram