Reverse detection of combustion furnace

The combustion furnace uses a high-voltage, high-frequency oscillating circuit to form an instantaneous large current to ignite the sample, so that the mixed gas generated after the sample is rapidly burned under oxygen-rich conditions, through a chemical analysis program, quantitatively and quickly analyzes the carbon and sulfur content of the sample equipment. The customer is a steelmaking plant, and the combustion furnace needs to be inspected and repaired due to frequent use.

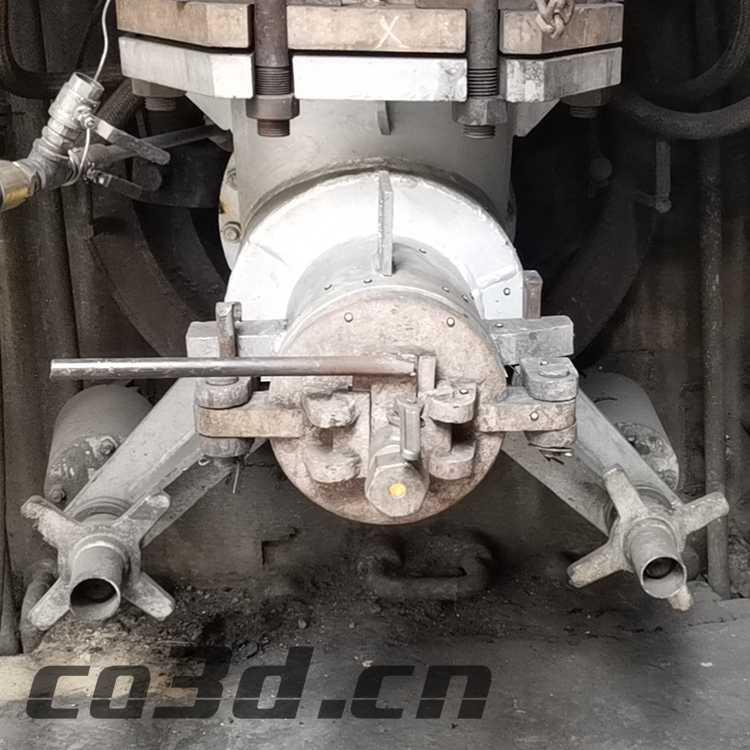

On-site physical map

On-site physical map

Practical problems

The temperature of the gas stove is as high as 198 degrees Celsius, which requires extremely high equipment. Due to the high temperature, the general marking points cannot withstand high temperatures and cannot be used. Custom magnetic marking points are required. Because the machine is too bulky and difficult to disassemble, it brings certain challenges to the scanning work.

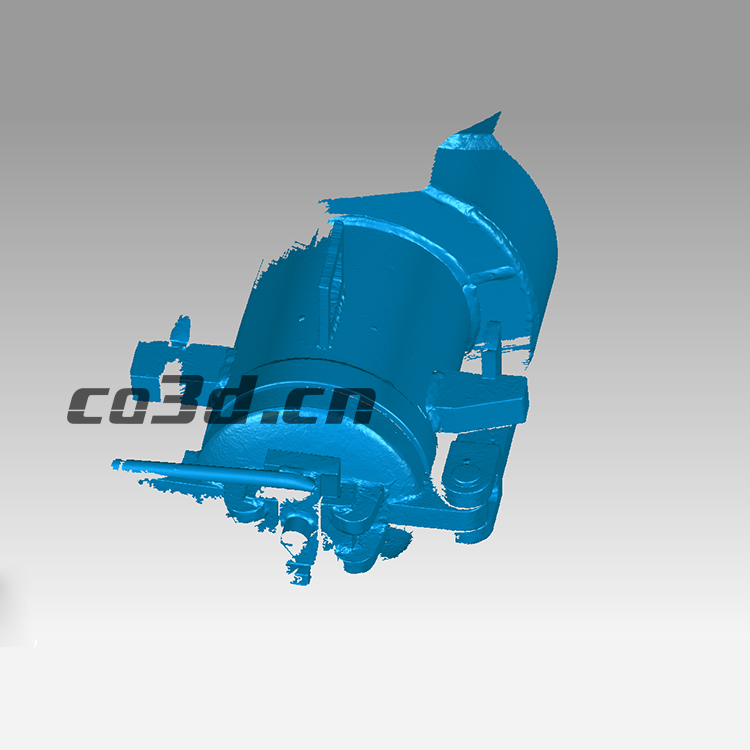

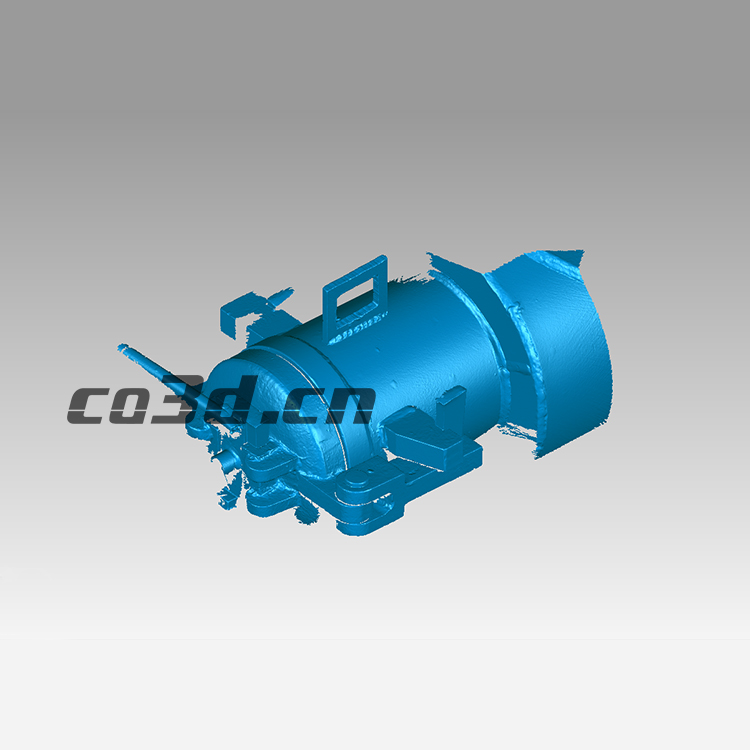

STL data graph

STL data graph

Huaguang solutions

Use the handheld three-dimensional scanner HOLON751 to scan the combustion furnace comprehensively and obtain high-precision data. HOLON751 has a total of 20 laser lines, with fast scanning speed, high data accuracy and stronger stability. The collected data can be imported into the 3D inspection software to analyze the damaged part. Reverse design software Geomagic Studio was used for secondary design of the combustion furnace for later maintenance. Help customers solve actual problems.

Site scan