air conditioning pipeline three-dimensional inspection case

Nowadays, labor is gradually replaced by machines, and product processing and testing are also fully automated. An air-conditioning production plant is developing towards full automation. Previously, the air-conditioning pipelines were manually tested. Now, 3D scanning is used to quickly acquire pipeline data and intuitively compare and test.

Practical problems

1. The customer has very high precision requirements for the three-dimensional data of the air conditioning pipeline, and the overall error needs to be controlled below 0.02mm.

2. It is necessary to accurately position the relative position of the air-conditioning pipe diameter. The data of the air-conditioning pipeline obtained by the traditional measurement method is insufficient, and the quality inspection of the product cannot be performed.

Co3d solutions

The customer factory is gradually moving towards automated production, and it is also a necessary step to replace the labor with the machine. After learning that the 3D scanner can efficiently and accurately obtain the air conditioning pipeline data for testing, contact our company. After understanding the detailed needs of customers, Huaguang engineers provided professional solutions—three-dimensional scanner (3DS) reverse design software (such as Imageware, Geomagic Studio) + three-dimensional inspection software to assist the company in research and breakthrough of high-end technology.

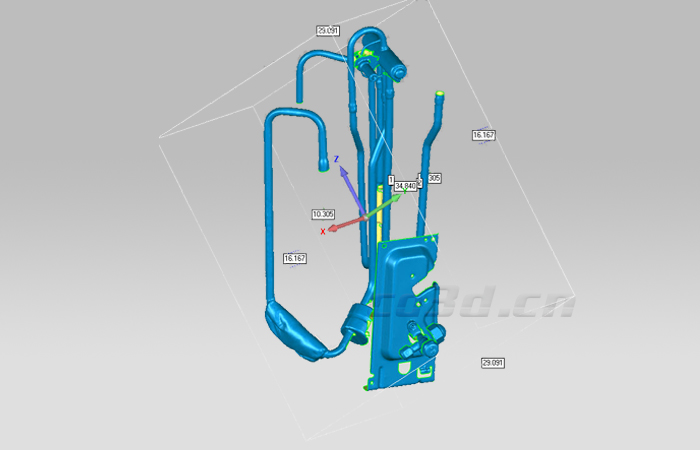

The sample data was collected using a 3D scanner (3DS), and point cloud data post-processing was performed through Geomagic Studio software points. The processed data import detection software (Geomagic Qualify) can directly obtain the spacing of the air conditioning pipelines, and at the same time capture and reflect the shape and shape deviation of the profile. The traditional detection software can only make a simple deviation comparison between CAD data and scanned data. Geomagic Qualify inspection software automates the alignment of measurement data with CAD data for fast alignment and quality control.

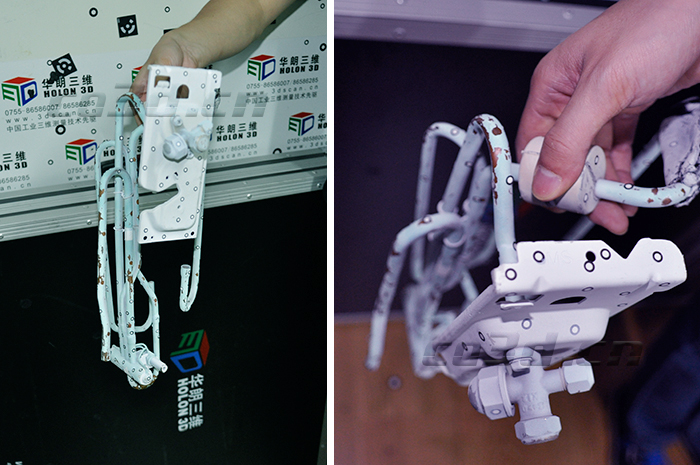

air conditioning pipeline scanning preparation

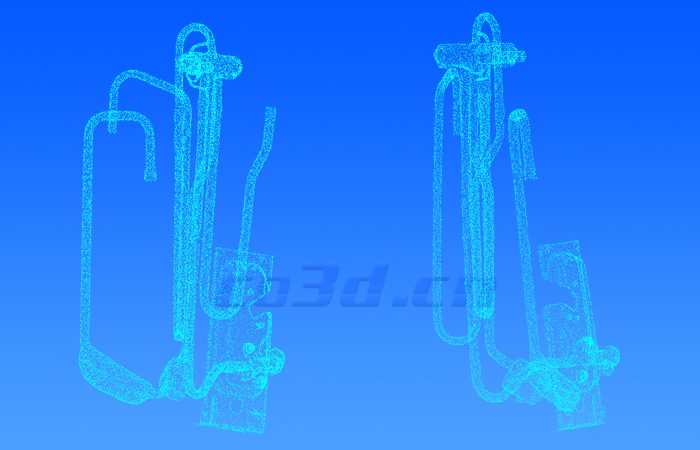

air conditioning pipeline point cloud data

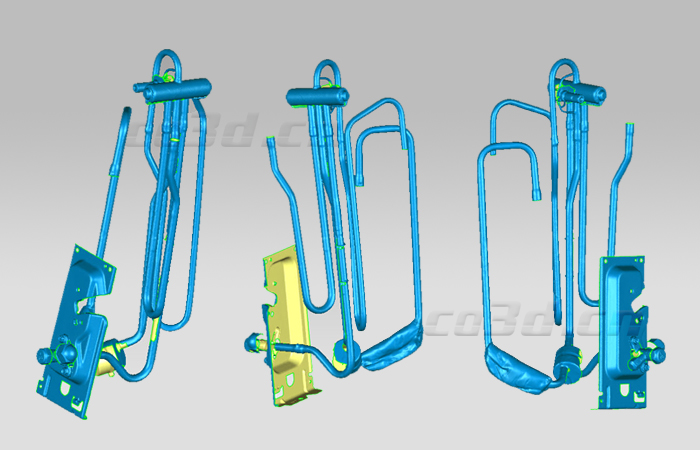

US air conditioning pipeline STL data

US air conditioning pipeline comparison test data