Three dimensional scanning case of hydraulic disc milling cutter

Huaguang engineer to scan precision cutter using 3D scanner HL-3DM, a cutter 3D model accurate file (CAD drawings), for the detection and quality control of the retrofit design and follow-up quality.

Practical problems

1, the shape of the disc milling cutter is complex, the hole position is much, the efficiency of the traditional measuring instrument is very low.

2, disc milling cutter is not only smaller size, but also more common, the use of ordinary three-dimensional scanner can not get its accurate 3D data.

CO3Dsolutions

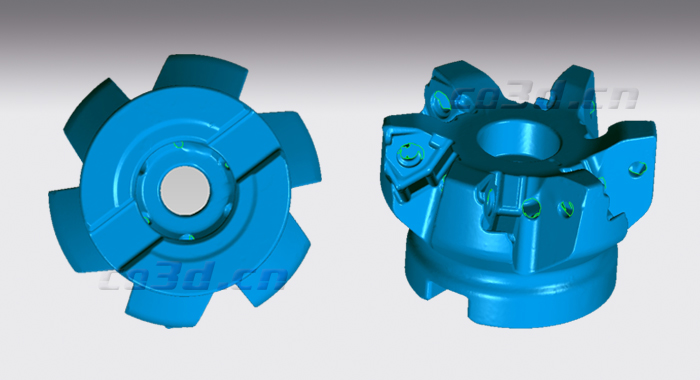

Is the milling cutter in machining process, a cutting tool milling plane, is called a mile, screw fixed blade position if there is a big error, may directly lead to the workpiece scrapped. Huaguang engineers proposed solutions, using industrial grade HL-3DM 3D scanner (precision), 3D data acquisition cutter, and postprocessing by Geomagic Studio software, the cutter point cloud data into triangular mesh data. A high precision 3D digital model of disc milling cutter is obtained.

The data can also be processed into the detection software to be able to conduct a detailed analysis of the characteristics of the object, such as the hole position, contour, curvature, etc., but also to capture and reflect the profile deviation. Qualify Geomagic detection software can automatically complete the measurement data and CAD data of the coordinate system, so as to achieve rapid detection and quality control.

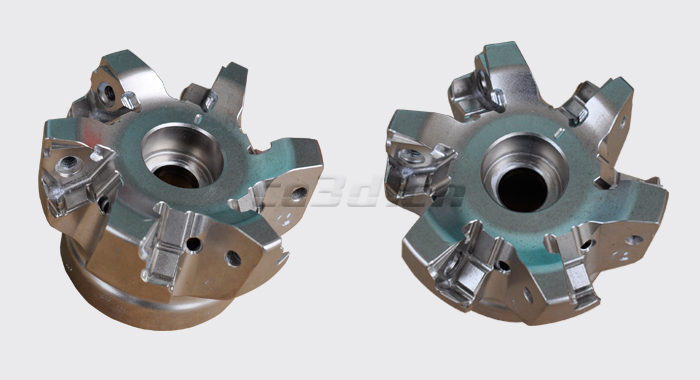

Disk milling cutter physical map

Disk milling cutter physical map

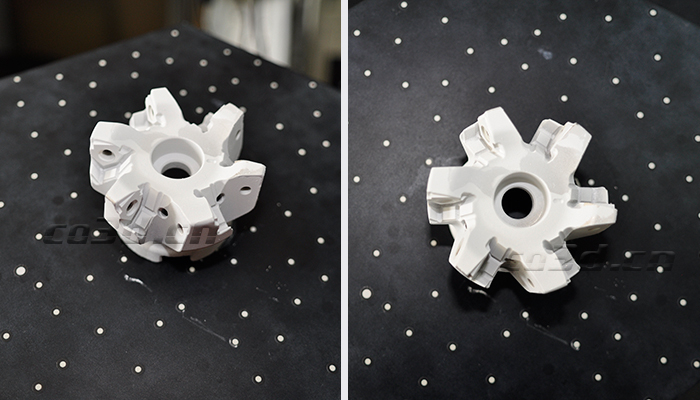

Disk milling cutter point cloud data

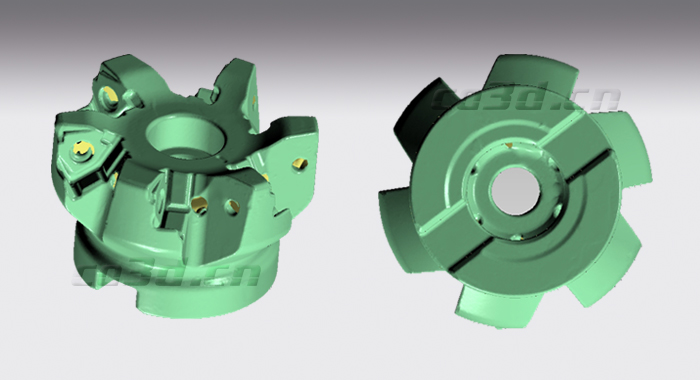

Disk milling STL data