3D inspection of door frame

Nowadays, the pace of social development is getting faster and faster, the demand in all aspects is constantly improving, the competition is fierce, and improvements are needed. A domestic auto company needs to test the off-road vehicle door frame and quickly obtain accurate data for comparison, so as to make reasonable modifications, improve production efficiency and save costs. Using the Hualang 3D scanner for 3D scanning to get the data is very good for the customer's desired effect.

Off-road vehicle scene map

Practical problems

It is necessary to scan the door frame components in the whole vehicle, and the door frame area is large, the contour size is different, and the peripheral hole positions are large and small. Using a conventional three-dimensional scanner, the scanned data map does not accurately represent every detail of the workpiece, and the data accuracy is not high.

Car door scene

Co3d solutions

According to the problem of the scanning door frame, the scanning surface has different contour sizes and small hole positions. Hualang 3D engineers proposed to detect the door frame with the hole position as the reference. The HL-Scan 3D scanning system can quickly complete the 3D inspection of the workpiece, and the scanning speed is faster, the precision is higher, and the stability is stronger.

Car door scene scan

Equipment: HL-Scan 3D scanning system

HL-Scan 3D scanning system can realize automatic positioning of target points without arm or other tracking equipment; the obtained point cloud data has no layering, automatically generate 3D solid graphics (triangular mesh surface); adopt 7 pairs of cross laser beams + extra 1 laser, scanning speed of 480,000 measurements / sec;

It can be hand-held for any scanning, no need for fixed installation, convenient to carry around, wide application range, scanning in narrow space, no requirement for working environment, ignoring complicated factors such as workshop vibration; 17.6m3 large working space, expandable (can be established Dynamic coordinate system), carbon fiber material, strong stability; black, high-brightness, color surface can be directly scanned, no stickers, that is, swipe, no pre-treatment, fast installation and use, true high precision, up to 0.02mm .

Car door scene scan

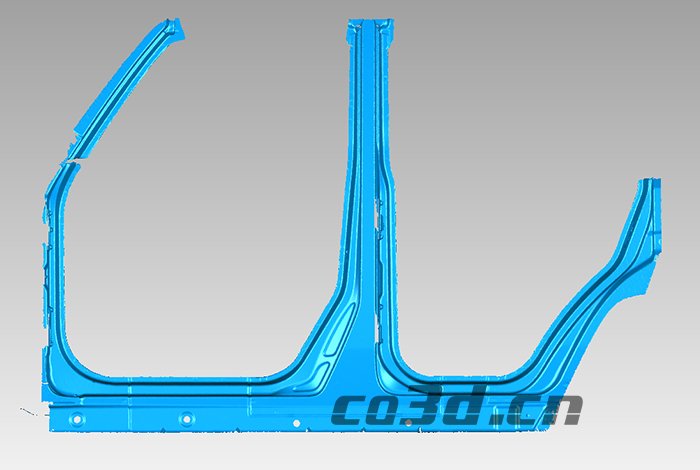

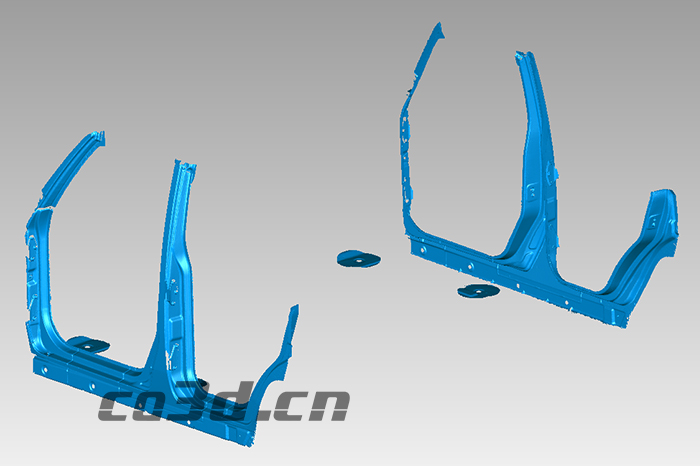

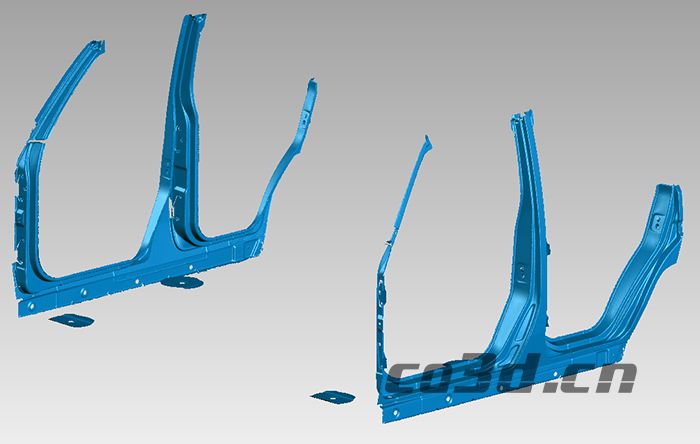

Door STL data chart

Door STL data chart

Door STL data chart