Reverse detection of 3D scanning of mold

This is a national key project. The customer spliced the workpiece together to detect whether the workpiece was deformed under various simulated weather environments. We found that our company uses a new measurement method, the three-dimensional scanner, to scan the product for various environmental measurements. Data comparison, corresponding improvements can be made to the workpiece, suitable for later work.

Mold scan scene

Practical problems

The customer needs to scan the mold before and after various environmental measurements. The mold is relatively large and difficult to move, and the overall structure is relatively complicated, which makes scanning difficult.

When using traditional measurement methods, the work process will be time consuming and laborious, and customers require the fastest time to complete the work with high quality. Therefore, traditional measurement methods cannot satisfy customers.

Mold scan scene

Co3d solutions

After communicating with the customer, our engineers took the handheld 3D scanner HOLON751 to the customer's site to demonstrate. First, a scanner is used to quickly scan the mold to obtain the original high-precision 3D data, and then the mold is measured under various weather conditions and scanned to obtain high-precision data.

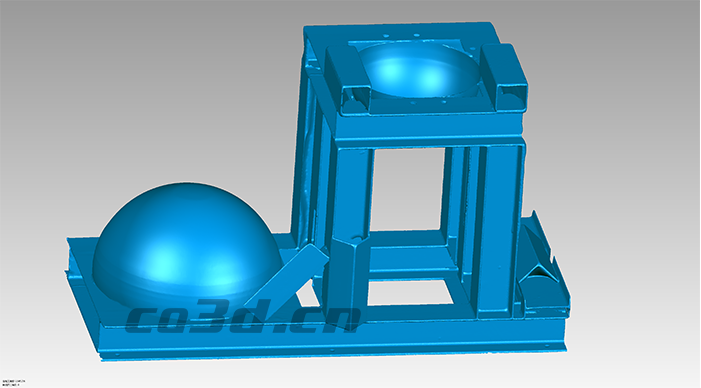

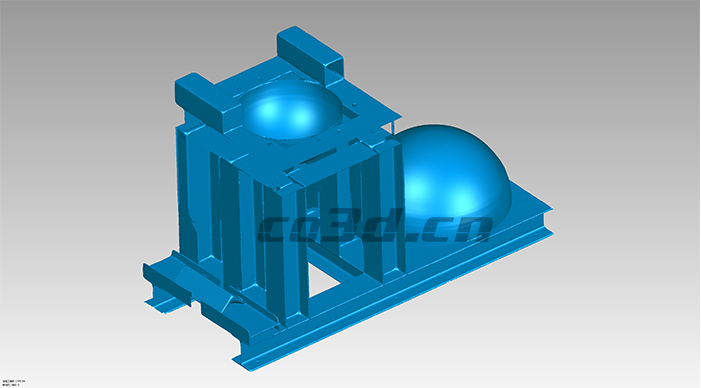

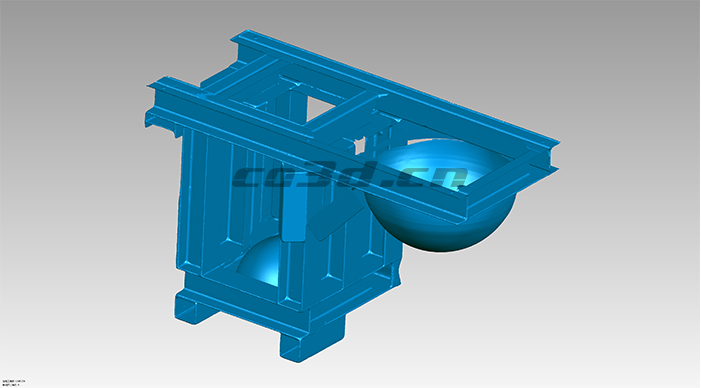

Mold STL data chart

The device scans extremely fast and can easily scan medium and large objects, greatly improving scanning efficiency. In addition, the measurement data has high accuracy, strong scanning stability, easy to use, and wide application range. Then import the scanned 3D data into the 3D inspection software for processing, compare and analyze the original data and the measured data, and detect the differences between the two data of the mold, whether there is deformation, and the severity of the deformation. The customer is very satisfied with the entire scanning demonstration process, and the accuracy of the acquired data meets the customer's requirements, which can help the customer to solve the subsequent difficulties. After the customer purchases the equipment, it can also be used to scan other workpieces.

Mold STL data chart

Mold STL data chart