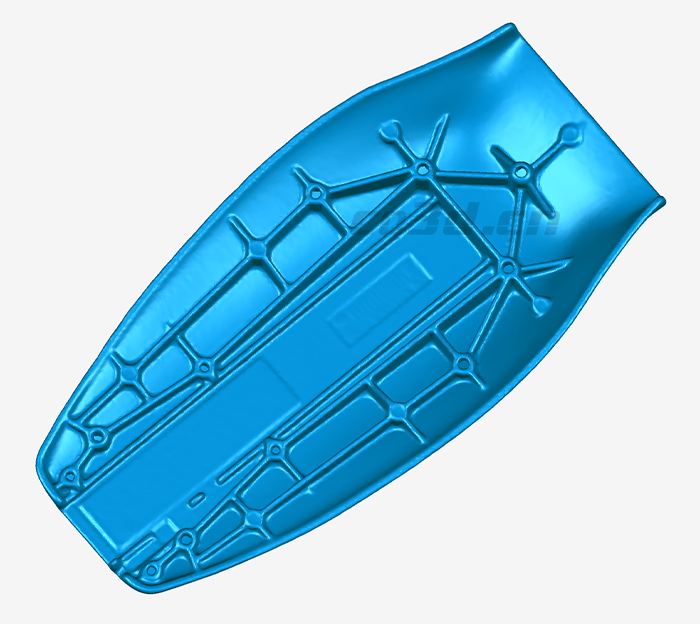

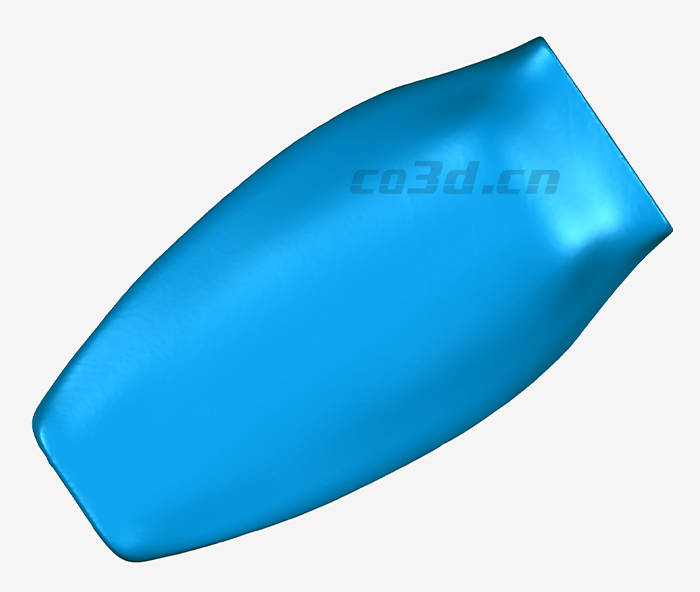

3D scanning of plastic parts

Plastic parts are widely used and are replacing traditional metal parts in different fields to achieve the goal of simplifying product structure and saving manufacturing costs. While demand increases, the speed of production must also be accelerated. With the development of 3D scanning technology, it is widely used and can scan to obtain object data for later design changes, product development, and speed up production efficiency.

Site scan

面临问题| Practical problems

The structure of scanning plastic parts is complicated, the surface has holes, and the corners are easy to form dead corners. Customers require that they cannot be sprayed and applied. The scanning work can be completed quickly and the scanning data accuracy is high. Using the traditional scanning method, scanning is time-consuming, cannot complete the complete scanning work, and the data accuracy is not high, which makes the scanned data unusable and cannot solve the problems faced.

Site scan

解决方案| Co3d solution

The solution is to use handheld 3D scanner HOLON751, the single-machine measurement accuracy is up to 0.01mm, the single scan range is large, the operation is flexible, fast and convenient, and the speed is fast. According to customer requirements, it is not possible to paste dots and spray powder, so mark points are pasted around the scanned samples for splicing, and a handheld 3D scanner is used for comprehensive scanning to obtain high-precision data.

Site scan

Import the acquired data into the 3D inspection software for inspection and analysis, and export inspection and analysis reports.

Site scan

Compared with traditional inspection methods, the new 3D scanning provides more convenient technology, improves work efficiency, reduces time waste, and speeds up production.