Tubing is a pipeline that transports crude oil and natural gas from oil and gas reservoir to the surface after drilling, which is used to bear the pressure generated in the process of exploitation. Therefore, it is easy to be damaged in the process of use, which will affect the use of the function. Therefore, it is necessary to use the 3D scanner to collect the data of the tubing, make comparative analysis, check the existing problems, and make changes in time, so as to avoid affecting the subsequent work arrangement.

Site scan

Practical problem

Due to the influence of shape characteristics, the traditional 3D scanning equipment can not collect accurate data. So customers want to find a 3D scanner that can solve this problem.

Site scan

Co3d solution

Our company uses a hand-held three-dimensional scanner, holon751, to conduct a comprehensive scanning of the tubing through a non-contact way, collect data, and complete the scanning work within 10 minutes. Holon751 has the advantages of fast scanning speed, high data accuracy, flexible and convenient scanning process, which can reduce the consumption of time and improve work efficiency.

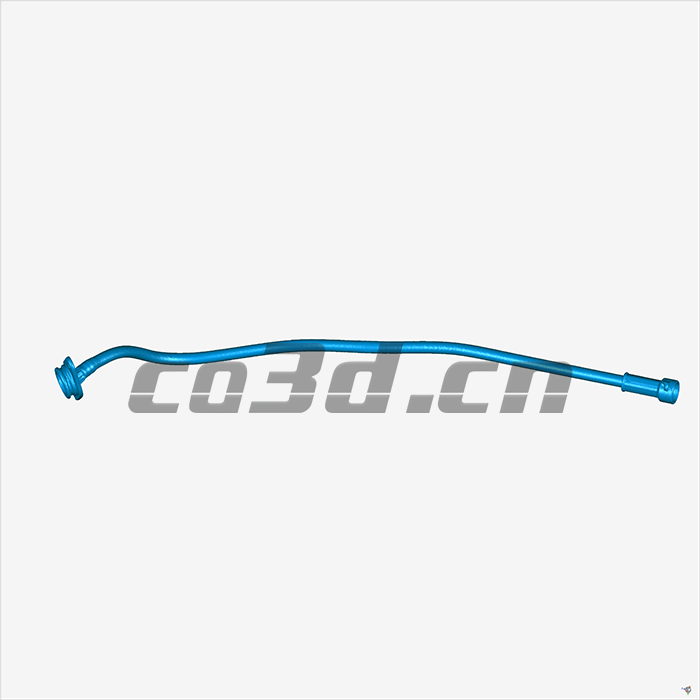

STR data graph

By importing the collected data into 3D testing software for processing, a simple and easy to understand comparative analysis report with the original digital model can be derived. Therefore, the existing problems can be understood, adjusted and optimized, and higher quality products can be produced, the utilization rate of products can be improved, and the cost can be reduced.

STR data graph

STR data graph