Three-dimensional inspection of audio shell

The audio frequency is extremely high now, and it is used in many occasions or at home. The market produces speakers that are small in size and easy to carry according to their needs. The high-power output is suitable for outdoor use or placed at home. The small and exquisite style has high requirements for the installation hole position, and the hole position needs to be tested to avoid errors in the assembly.

On-site entity map

On-site entity map

Practical problems

The speaker shell is small, with many holes in the inside, and the design is more complicated. The customer uses the machine assembly line for production and installation, and each step must be set up in advance without making mistakes. It is necessary to accurately know the spacing between the holes and make early adjustments.

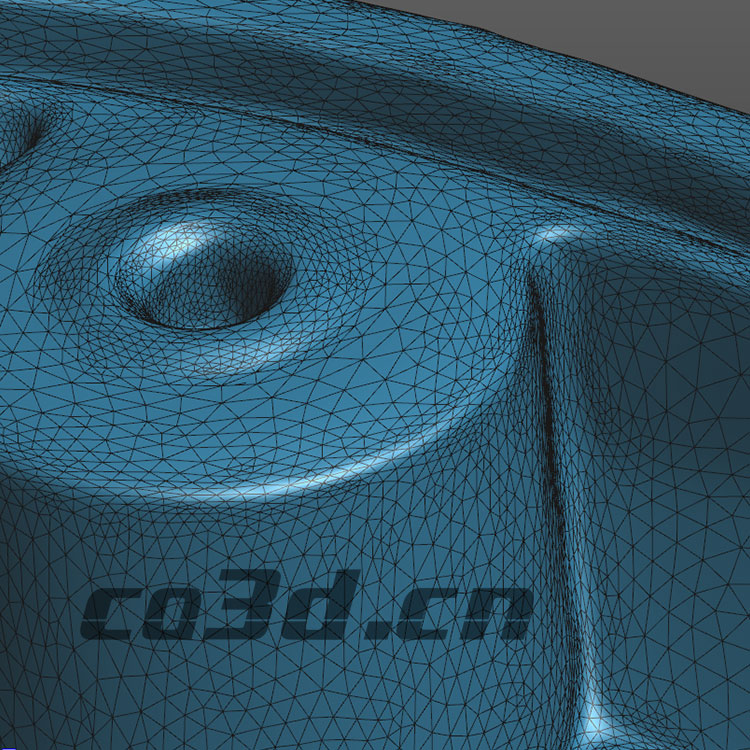

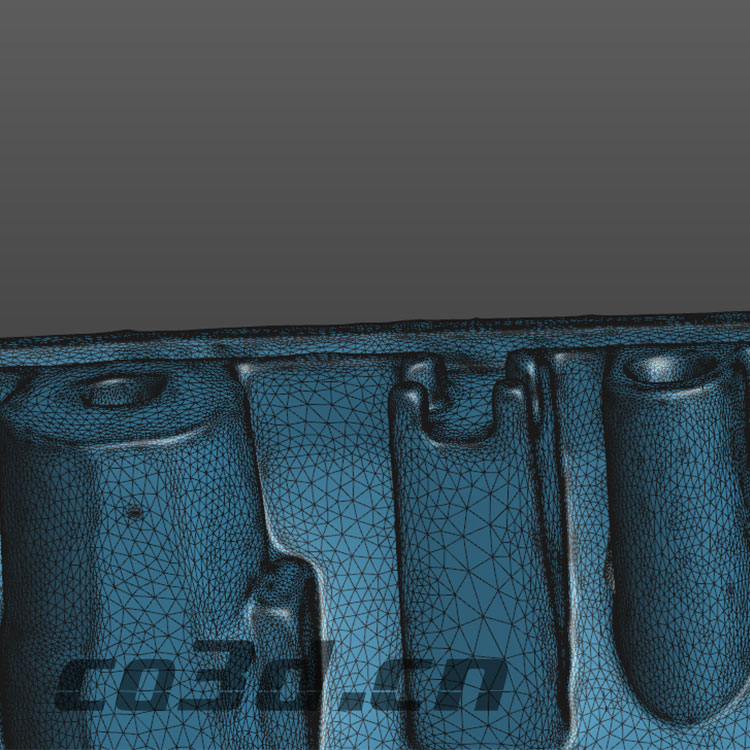

STL scan chart

STL scan chart

Huaguang solutions

Use the handheld three-dimensional scanner HOLON751 to scan the audio shell to obtain high-precision data. The handheld scanner has 20 laser lines, and the scanning speed is fast; the deep hole scanning mode can accurately scan the hole position, and the fine mode can accurately scan the small part, and the data collected has high accuracy. Import the data into the 3D inspection software for analysis, and get the spacing between the holes clearly.The handheld 3D scanner can accurately obtain high-precision data, and obtain accurate reports through data analysis, which provides great help to customers.

Right analysis graph