3D scanning of shoes

Shoes are worn on the feet to protect the feet and are easy to walk on. They need to fit comfortably. As a necessity, with the emergence of different requirements, there are more and more types of shoes, that is, to feel comfortable and beautiful and practical, and to prevent slipping on the soles. A shoe factory company finds that our company scans the shoes to obtain data and make shoe molds, which is convenient for mass production of different sizes in the later stage.

On-site scan of shoe mold

Practical problems

With the traditional measurement method, only the general contour data can be obtained. For the surface and curved surface and some parts with large slopes, it is impossible to measure and complete data cannot be obtained.

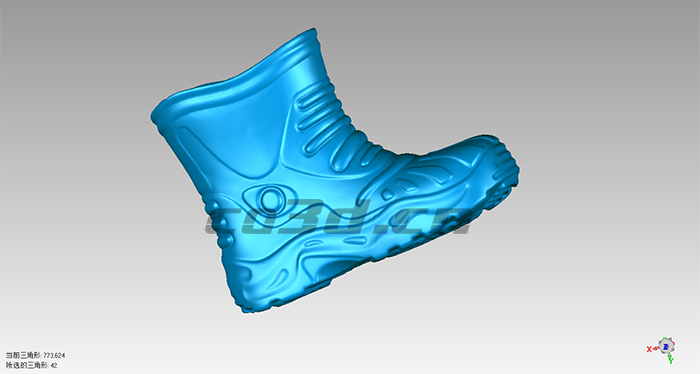

Boot STL Data Map

The surface of the shoe has a texture design, and the grooves on the sole are clear. It is mainly used for non-slip. Therefore, the scanned data needs to be complete and accurate.

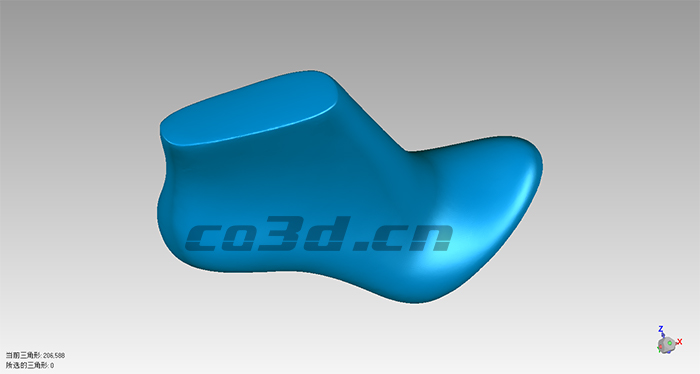

STL data map

Co3d solutions

Use our hand-held 3D scanner HOLON751 to scan customer samples. The first is full dusting, and then the identification points are affixed, which is mainly conducive to equipment identification, positioning and stitching. Then use the handheld device 751 to quickly and comprehensively scan the shoes. It takes less than ten minutes to complete the scan and obtain high-precision data. The texture of the shoes is clear and the data is complete. The customer was satisfied with the entire scanning process, and the data results also met the requirements.

Boot STL Data Map

HOLON751 handheld design, convenient operation, fast scanning speed, high accuracy, stronger stability, automatic stitching technology and independent research and development of scanning software to improve scanning accuracy and work efficiency, single machine measurement, easy to scan large and medium-sized objects.

STL data map

STL data map