Racing car body 3D scanning program

CO3D commissioned by a well-known car companies, car vehicle scanning 3D data, optimize the performance of the car. In the understanding of the actual situation, the use of three-dimensional 3D Technology Engineer Huaguang Photogrammetry System HL-3DP + 3D scanner HL-3DW, quick access to car body and wheel arch data, optimization of drag racing.

Practical problems

1, the traditional measurement method of data acquisition density is not enough (data) and the surface of the body and the curve can not be measured, can not be normal detection, the latter can not reverse the drawing. Heavy workload, low efficiency and accuracy is not high, can not reach the customer requirements.

2, scan the car body and the wheel arch, optimize the body structure, so that the car has a better flow of linear. The car body length 4.5m width 2.3m, general 3D scanner scanning format is small, large objects when the cumulative scanning area too much. Can not find the signs and splicing is not a good question. Generate a large amount of work, low efficiency, and the accuracy of the data can not reach the customer deman

CO3Dsolutions

The use of traditional methods not only spend a lot of time and huge investment, can not meet the actual requirements of the team. According to the three-dimensional problem of Huaguang team are the use of the proposed solution: 3D photogrammetric system (HL-3DP) + 3D scanner (HL-3DW) to get the car body and wheel arch data. The car gets out of the car after the appearance of manufacturing data model wind tunnel experiment, test the drag coefficient.

Racing physical map

1, the preparatory work

Spray imaging agent: improving the sample surface color contrast scan data to obtain better.

Marking point: the data obtained in the scanning software to carry out the positioning and splicing.

Point to point: make the 3D photogrammetry system to obtain the 3D coordinates of the object surface.

Car body mount point

2, 3D Photogrammetry

Get the body surface 3D coordinate body design in addition to be in line with the streamline, but also to take into account the smooth flow of the chassis. The scanning car shape length 4.5m width 2.3m, Huaguang engineers first using 3D photogrammetric system (HL-3DP) shooting images of car body, the 3D measurement, HOLON3DP software will automatically combine these images after operation, 3D coordinates can be obtained for each encoding point center, calculate the coordinates of 3D the key point of the object surface information value.

Three dimensional Photogrammetry

3, three-dimensional scanning

The body surface 3D data into the HOLON3DS scanning system, the use of three-dimensional scanner (HL-3DW), fast access to high accuracy of the car body 3D data. The 3D scanner is scanning area, large portable design, fast scanning speed, high precision, high stability and other characteristics. Using 3D photogrammetric system (HL-3DP) and 3D scanner (HL-3DW) with can point cloud information for large area surface correction, greatly improve the overall accuracy of 3D scanner point cloud, improve work efficiency. Only need 1.5 hours to get the body data, the accuracy of 0.15mm.

Three dimensional scanning spot

4, wheel arch scanning

The wheel arch and wheel hub are the most suitable distance can effectively reduce the wind resistance. An important part of the optimization is improved so the wheel arch drag racing. Using the car lift to lift the car, the use of three-dimensional scanner (HL-3DW) from different angles to scan the wheel arch, access to the data of the wheel arch. Import data into a professional test software, calculates the wheel arch and wheel hub are the most suitable distance.

5, the introduction of three-dimensional scanner and the advantages brought by the three-dimensional Photogrammetry System

1 advantages: shorten development time, using data acquisition model, direct wind tunnel test, optimization of drag racing.

2 advantages: data interface widely, can be modified directly in the data.

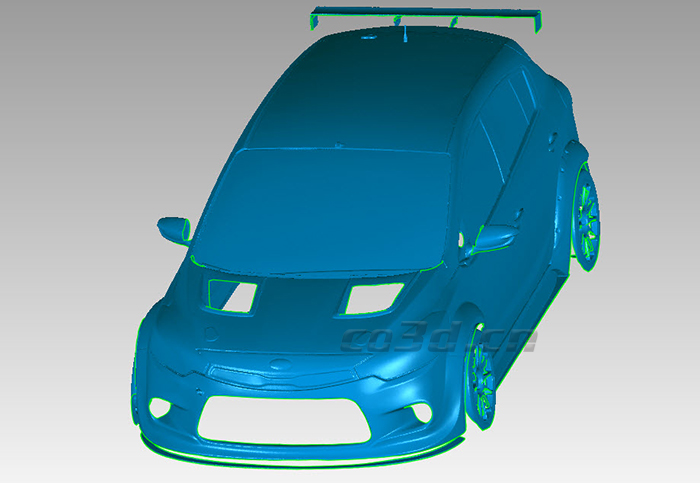

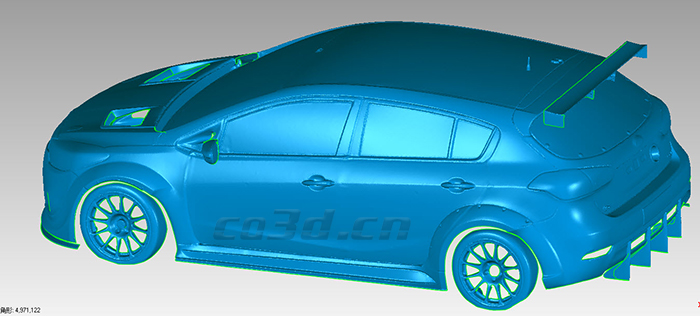

Car body STL data chart

Car body STL data chart