3D Scanning Case of Automotive Suspension System

Customer is a well-known automotive parts manufacturing enterprise in China. Customers need to scan automotive suspension system in three-dimensional, obtain high-precision three-dimensional data and reverse modeling to make technical reserves for later product improvement and upgrading.

Practical problems

1. It is very tedious and time-consuming to measure the automobile suspension system by using traditional methods (such as checking fixture, fixture, three coordinates, etc.), and it is not easy to measure and test the automobile suspension system accurately and quickly.

2. Vehicle suspension system is complex and irregular in shape, and there are many curved surface contours. Customers need to accurately measure the hole position of the vehicle suspension system. It is difficult for traditional three-dimensional scanners to quickly and accurately obtain high-precision three-dimensional digital models.

Car rendering

Huaguang's Solution

Customers need to carry out three-dimensional reverse modeling of automobile suspension system for product upgrading and improvement in order to improve market competitiveness. Therefore, Huaguang 3D engineers provide professional solutions: using hand-held three-dimensional scanner HOLON760+ (fast acquisition of high-precision three-dimensional data of automotive suspension system) and reverse design software (converting point cloud data of automotive suspension system into triangular mesh data) to assist the company in the secondary design of automotive suspension system.

Field Map of Automotive Suspension System

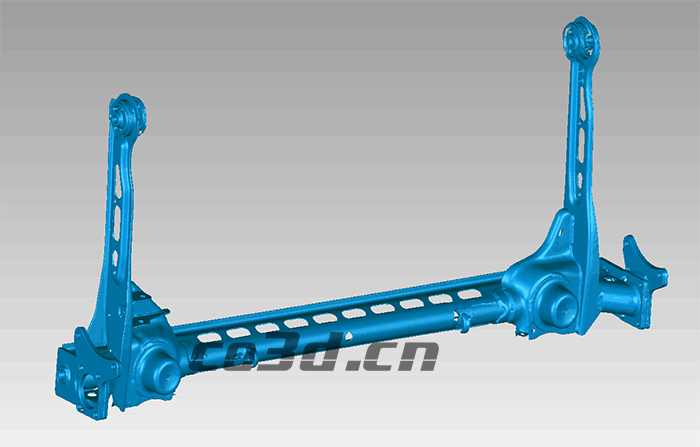

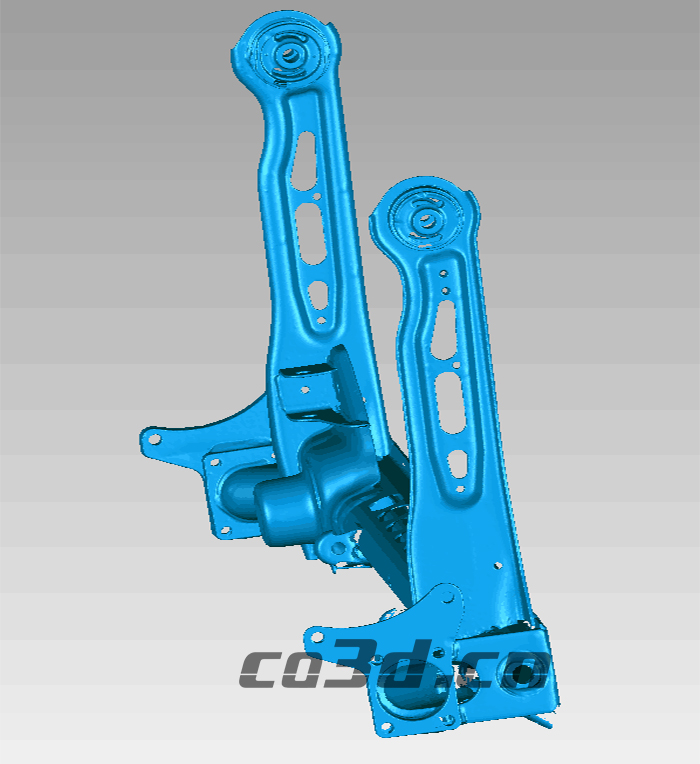

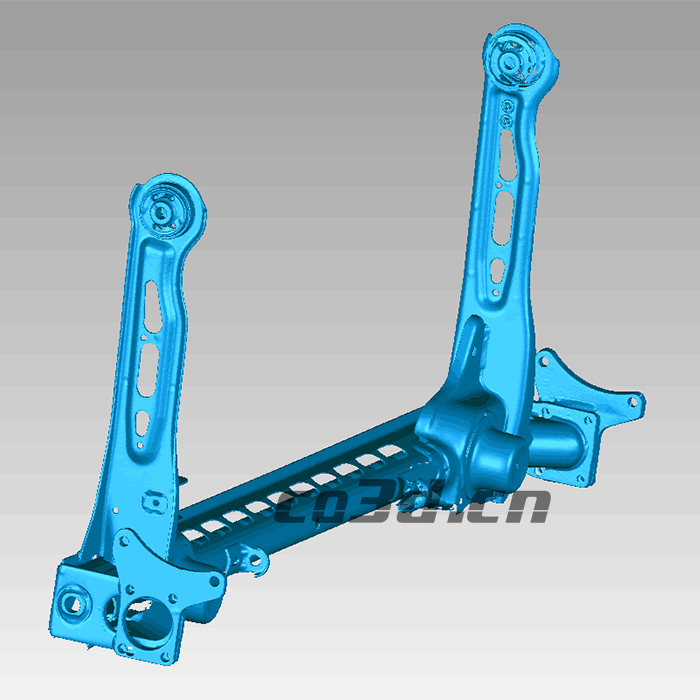

STL Data Diagram of Automotive Suspension System

STL Data Diagram of Automotive Suspension System

STL Data Diagram of Automotive Suspension System