Three-dimensional Inspection Case of Automobile Lamp Mould

In recent years, the rapid development of China's automobile industry has brought a broad space for the development of domestic automobile moulds. At present, the production of automobile moulds has accounted for about one third of the total production of moulds. A well-known automobile manufacturer in Guangzhou needs to carry out regular quality inspection of automobile lamp moulds, to detect the extent of die wear and tear, and to repair the moulds in the later stage.

Practical problems

Customer background:

Customer is a Sino-Japanese joint venture, which imports advanced Japanese automotive production technology. It mainly deals in the design and manufacture of automotive moulds and the development and manufacture of vehicle technology and equipment. The equipment and manufacturing technology are in the leading position in China.

Scanning object: three-dimensional inspection of automobile lamp mould

Inspection Requirements: Inspection of Automobile Lamp Die Loss and Late Three-dimensional Reverse Repair

Recommended solution: hand-held three-dimensional scanner HOLON 760 + three-dimensional detection software

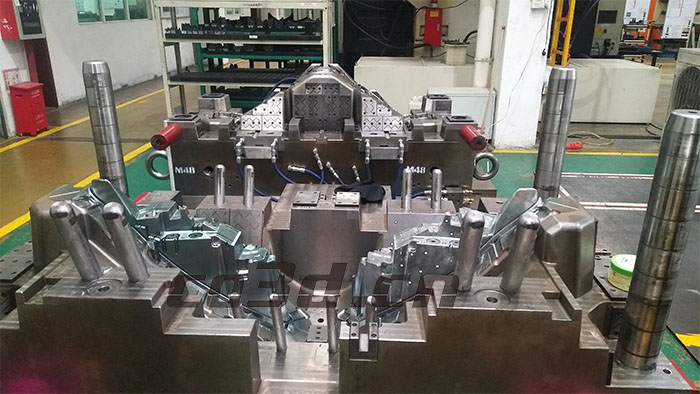

On-site physical drawing of automobile lamp mould

Detection difficulty

1. The automobile lamp die is bulky and inconvenient to move, and the whole surface is complex and irregular (with more curved surface and outline). The uneven shape of the lamp die results in more dead angles, which greatly increases the scanning difficulty.

2. Customers need to quickly acquire high-precision three-dimensional data of automobile lamp mold for mold wear detection and repair. Customers require that scanning can not spray imaging agent. It is not only difficult to adopt traditional scanning scheme, but also unable to meet customer needs.

Co3d solutions

Huaguang three-dimensional technical engineers fully understand the needs and problems of customers, and recommend the hand-held three-dimensional scanner HOLON760.

Product features: HOLON760 is a portable Blu-ray hand-held three-dimensional scanner independently developed and produced by Huaguang. Its advantages are as follows:

1.Ultra portable, the weight of the fuselage is only 0.87 kg;

2.The accuracy is as high as 0.020 mm and the resolution is as high as 0.050 mm.

3.Blue-ray laser: It adapts to indoor, outdoor and other complex environment measurement tasks, and has stronger anti-interference ability.

4.High-speed scanning: 14 laser lines (+1/5 extra beam), 480,000 measurements per second;

5.Large measurement space, good stability, single machine can complete the measurement of super large workpiece;

6.Almost unlimited 3D scanning, not affected by object size, material, color, etc., without powder spraying treatment;

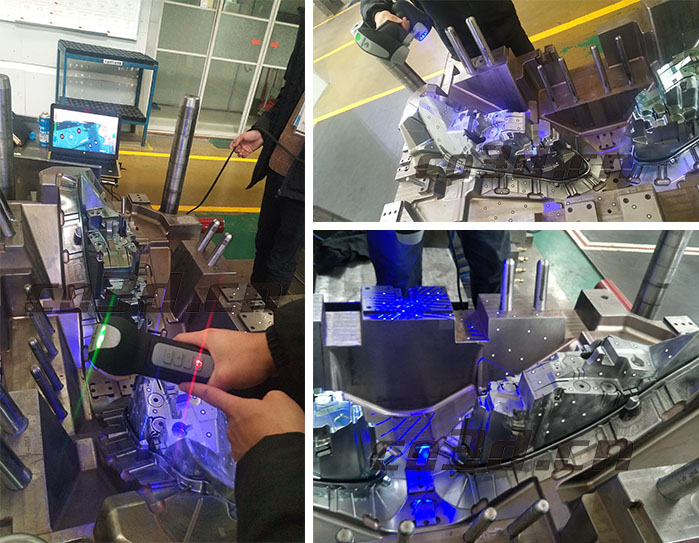

3-D Scanning Field Map of Automotive Lamp Die

HOLON760 features high precision and high efficiency, which effectively solves the difficulties of traditional scanning measurement and does not need powder spraying before scanning. It not only can quickly and accurately acquire the three-dimensional scanning data of all parts of the workpiece under test, but also can effectively solve the problem that the traditional method of automobile lamp mould can not meet the needs of customers. The effect is very satisfactory to customers. We have purchased our equipment (hand-held three-dimensional scanner HOLON760) to replace the traditional measurement scheme.

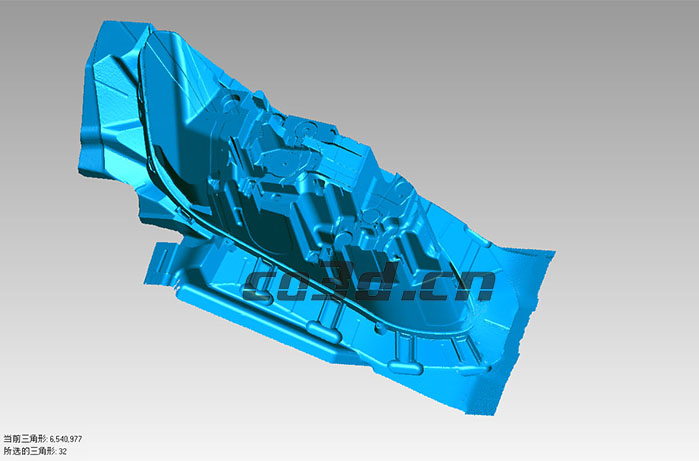

STL Data Diagram of Automobile Lamp Die

STL Data Diagram of Automobile Lamp Die

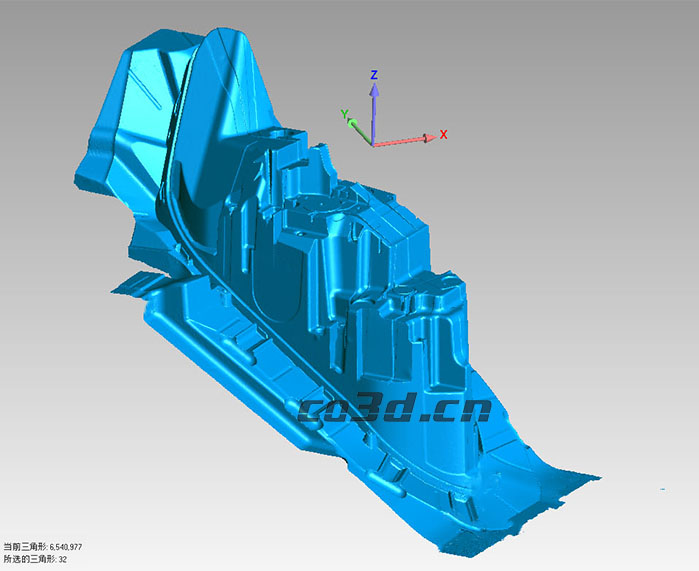

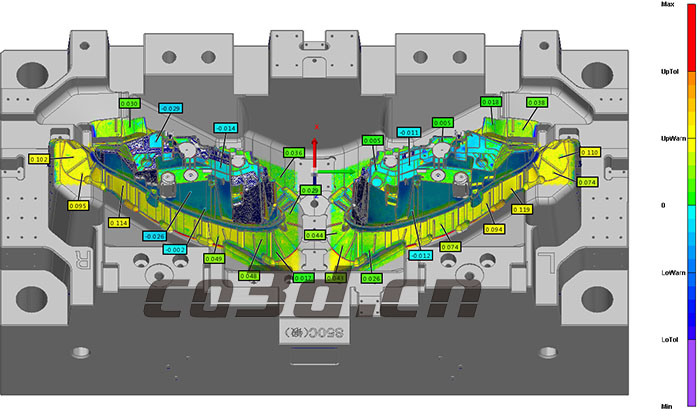

Data Diagram of Three-Dimensional Inspection for Automobile Lamp Die