Automobile shock absorber 3D scanning inspection

The shock absorber is a fragile accessory in the process of using the car. The working of the shock absorber will directly affect the stability of the car and the life of other parts. Therefore, the shock absorber should be tested, the fault repaired, and the shock absorber Often in good working condition. The customer wants to use the scanner to scan the shock absorber for comparison of test data and make adjustments.

Auto shock absorber real shot

Practical problems

The overall structure of the automobile shock absorber is complex, with many components, irregular surface details, different sizes, and surface reflection needs to be sprayed.

When using a conventional scanner, the scanning time is long and time consuming for complex workpieces. Moreover, the micro-detail features cannot be completely scanned and captured, resulting in low data accuracy and poor scanning results, which cannot achieve the desired results.

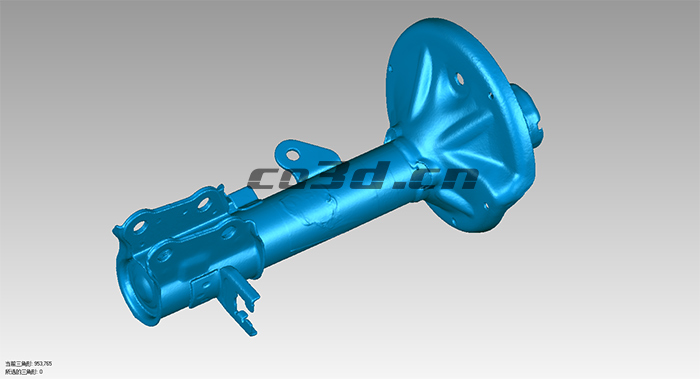

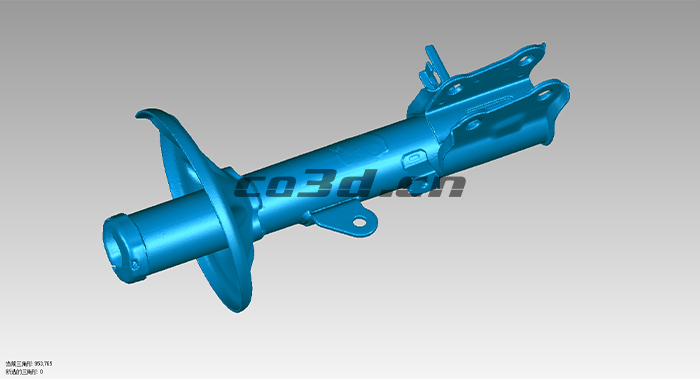

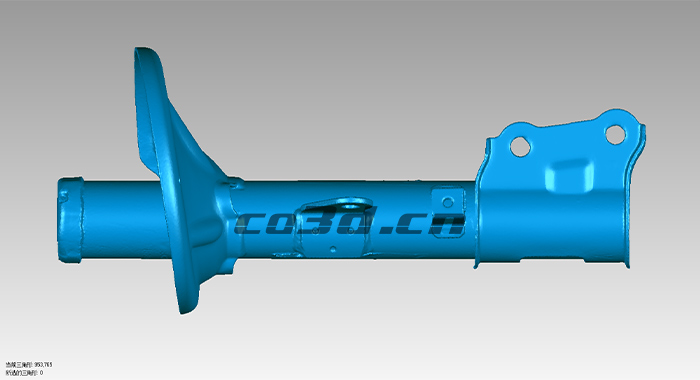

Car shock absorber STL data chart

Co3d solution

Shock absorbers have a great impact on the life of the car and the life of other parts. It is conceivable that quality assurance is very important. Engineers use the HOLON760 handheld 3D scanner with fast speed, high precision and stability. The device is light and portable, making it easy for customers to carry and use. The light source uses 7 sets of crossed laser lines plus an additional laser line for a total of 15 laser lines, which makes the scanning precision high, the capture speed is fast, saves time and improves work efficiency; it can also switch a single laser scanning mode to scan the dead angle, It brings great convenience to customers and is easy to use. It can also display in real time, sweeping out data, sweeping or sweeping incomplete, and finding completions in time, convenient and fast.

Car shock absorber STL data chart

After reading the demo, the customer feels that the device is easy to use and easy to use. After obtaining high-precision data and importing it into the 3D inspection software to generate a 3D data chromatogram, it can be compared with the original digital model. The customer is also very satisfied with the scanned data, which is in line with the desired effect and is also very large for the device. Recognition.

Car shock absorber STL data chart