Reverse scanning of auto parts

As the foundation of automobile industry, auto parts are the necessary factors to support the sustainable and healthy development of automobile industry. Without the independent brand of the whole vehicle, it is difficult for the R & D and innovation ability of the strong parts system to burst out. Without the support of the strong parts system, it will be difficult for the independent brand to continue and complement each other. Parts also need to do a good job of innovation, transformation and redesign, using 3D scanning modeling can effectively and quickly complete the innovation work.

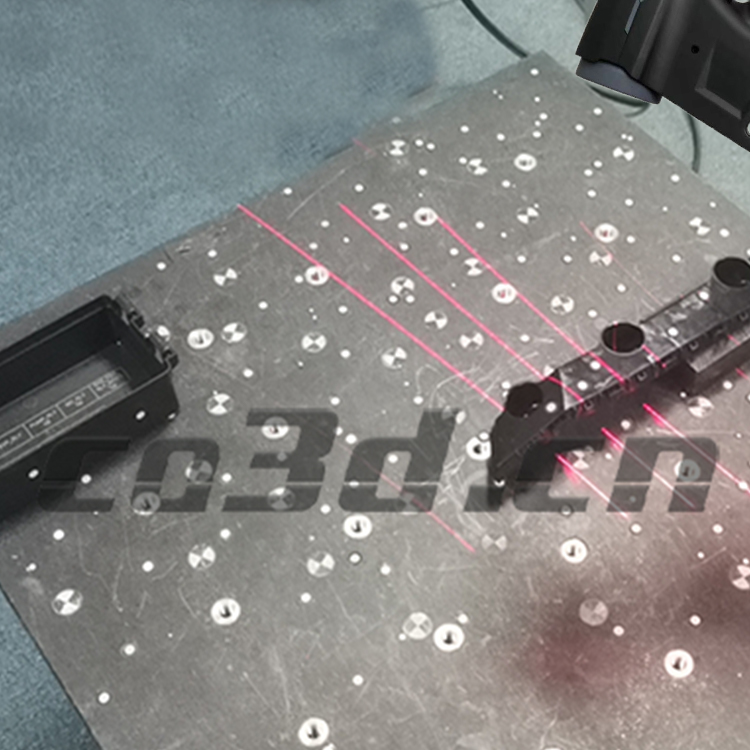

On site scanning of parts

Practical problems

There are irregular parts around the scanning part with deep holes. And the reverse transformation requires high data accuracy. In the past, the measurement time is longer, more time-consuming and more cost, so it is necessary to use three-dimensional scanning technology to improve efficiency and reduce cost.

On site scanning of parts

Co3d solutions

The holon751 is a hand-held three-dimensional scanner of Huaguang. Laser harness has high scanning speed, and single line mode is suitable for scanning deep holes and fine mode scanning small parts. A small number of identification points are pasted around the scanning sample, and the high precision 3D data is obtained by using the 3D scanner. The optimized data are imported into 3D reverse design for 3D model construction.

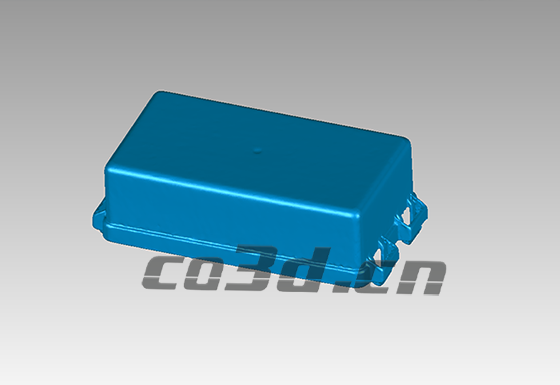

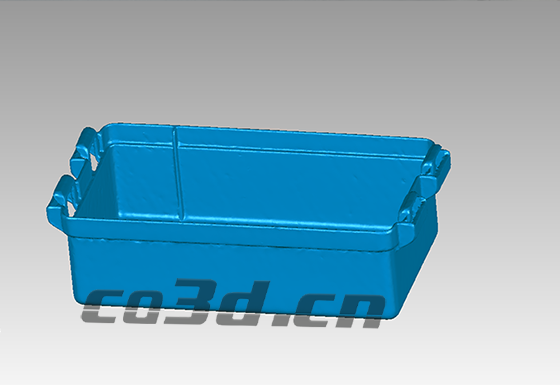

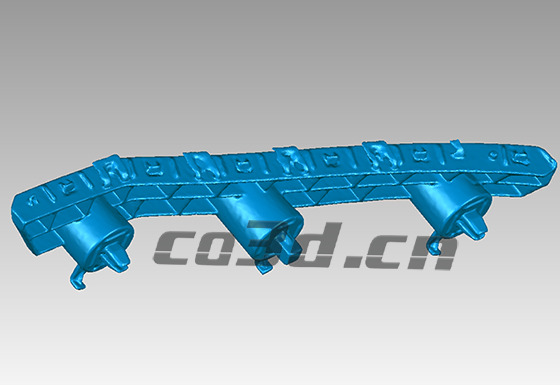

Parts scanning data chart

From 3D scanning to reverse 3D modeling, it helps customers solve the problems they face, improve work efficiency, reduce difficulties encountered in work, save working time and reduce labor cost, thus bringing greater benefits.

Parts scanning data chart

Parts scanning data chart