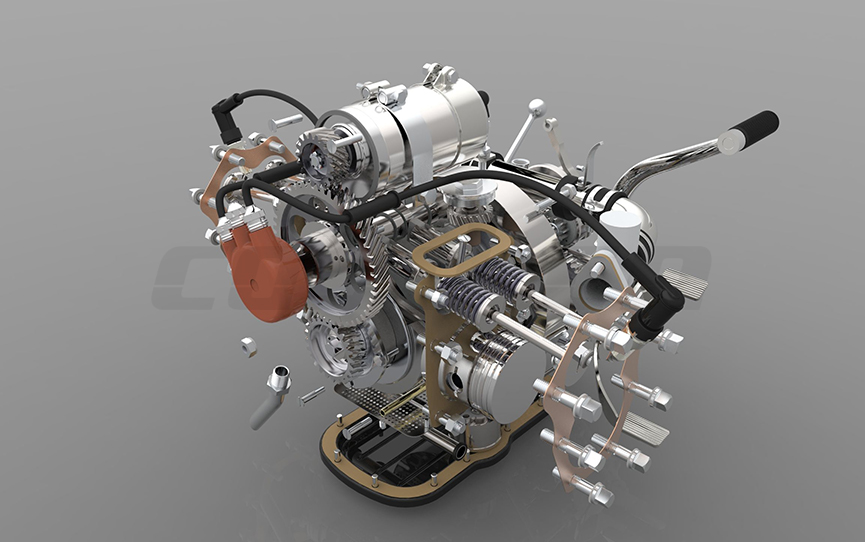

Automobile engine parts inspection

The engine is the heart of the car and provides power for the car to walk, which is related to the power, economy and environmental protection of the car. The designers of the engine constantly integrate the latest technology with the engine, turning the engine into a complex mechatronic product, and making the engine performance nearly perfect.

With the gradual improvement of the engine structure, the demand for dimensional inspection of engine parts is increasing. Engine manufacturers gradually need a high-precision three-dimensional inspection method for the inspection of engine parts to lay a solid foundation for the manufacturing industry

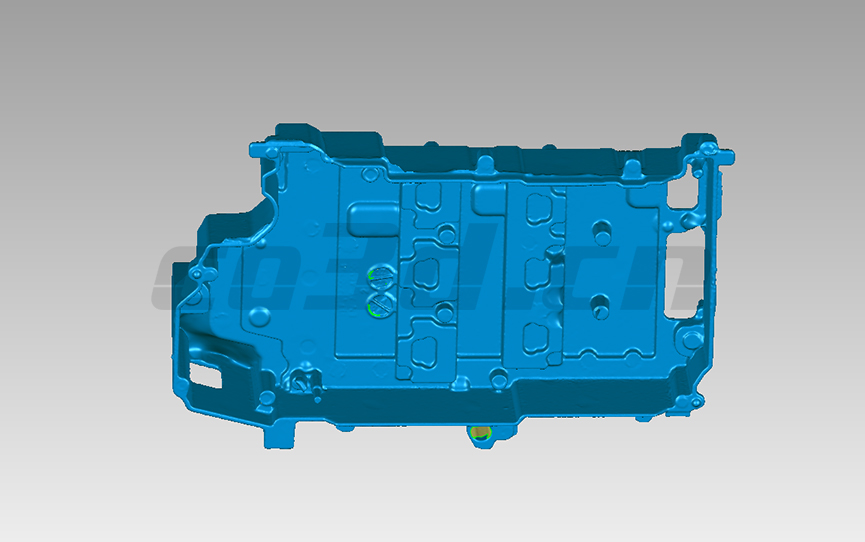

Structural drawing of automobile engine parts

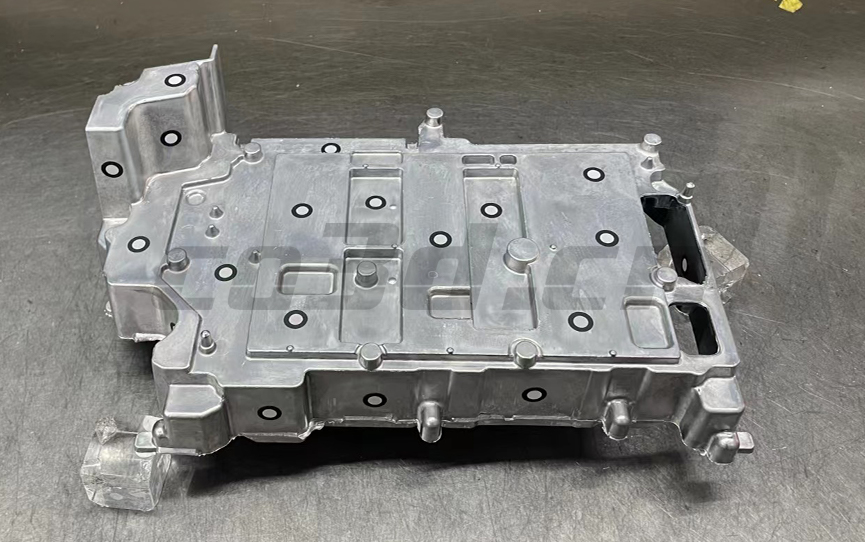

Site drawing of automobile engine parts

Practical problem

Engine parts are becoming more and more refined, with distinct features and uneven surface. The quality of measured data during scanning is very high

The time and cost of using the method to measure is large, and it is difficult to achieve the expected detection effect.

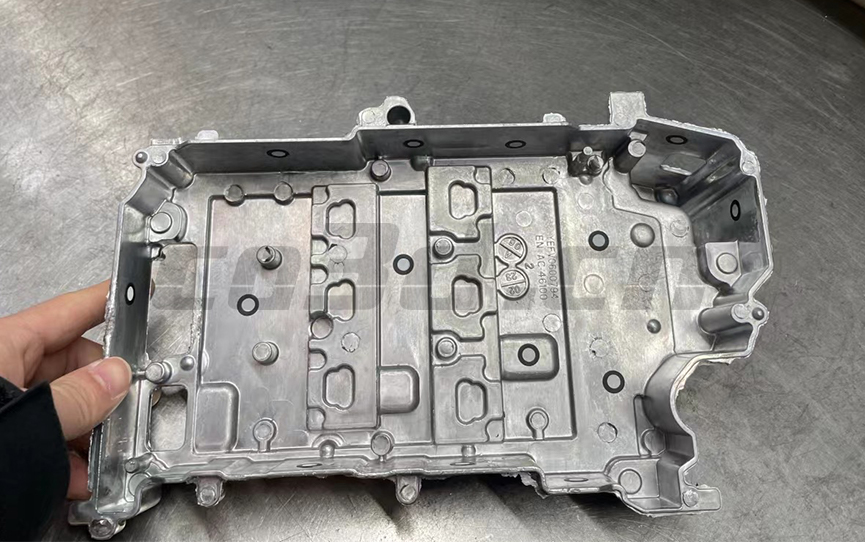

Site physical drawing

Site physical drawing

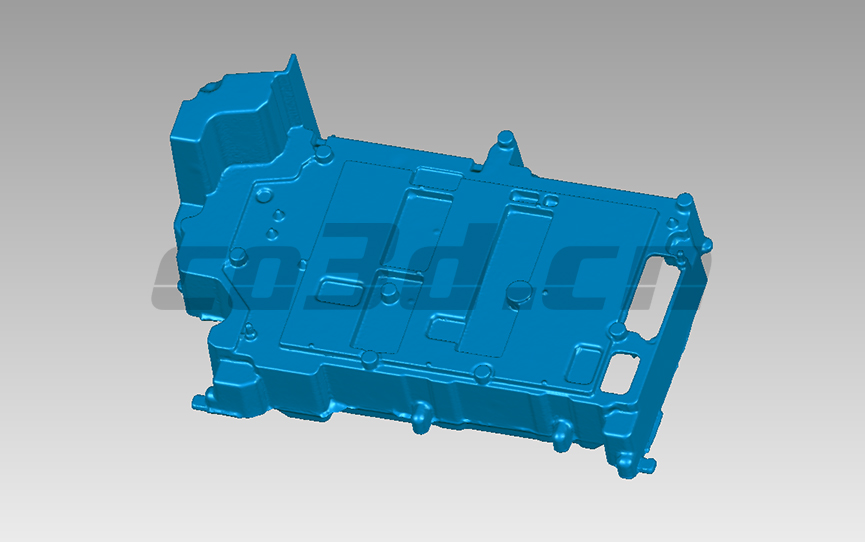

Solutions

Hand-held 3D scanner: Hand-held non-contact scanning greatly reduces the burden of scanning work. High-precision 3D scanning provides high quality assurance for the number of measurements in the early stage, facilitates the detection process, and highly compatible data format. The data analysis report can be obtained by importing the detection software with one click

In the whole process of engine manufacturing and testing, the efficient and convenient testing method of handheld 3D scanner has greatly improved the testing efficiency and added new impetus to the rapid development of the automobile industry.

STL data diagram of automobile engine parts

STL data diagram of automobile engine parts

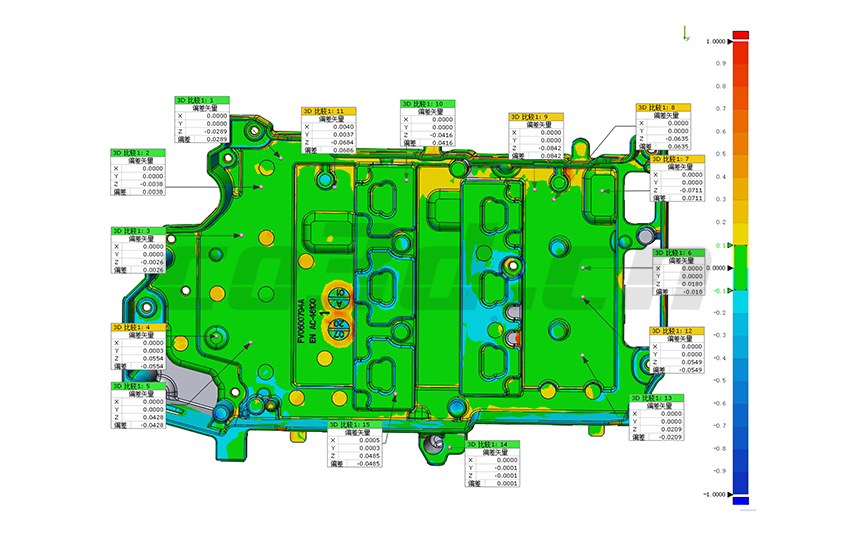

Comparative inspection chart of automobile engine parts

Comparative inspection chart of automobile engine parts