Su27 fighter joystick 3d detection

The three-dimensional model of the 3d scanner was used to analyze the 3d model of the fighter joystick by using Geomagic, and the three-dimensional model was analyzed to obtain accurate 3d data. Thus, the accuracy of product design is improved, and the design and processing cycle of product development is greatly reduced and the cost is reduced.

Practical problems

1, the fighter joystick is very tough to project technical indicators, the aircraft parts 3 d data accuracy is very high, need to control the overall error is very low, the traditional measuring method cannot satisfy the needs of customers.

2, the density of general measurement data collection is not enough (data) and the fighter joystick curved surface and curve can't measure, can't be measured normal, later also can't test quality and secondary design.

Su27 fighter joystick object map

CO3D solutions

The quality of the components directly affects the efficiency of the aircraft making, so the quality of the fighter's joystick is of particular importance. Uh guano used in 3 d engineer propose solutions: photo type 3 d scanner - 3 ds quickly get HL fighter joystick and high precision of 3 d data by reverse engineering software Geomagic Studio converts fighter joystick point cloud data to a triangular mesh surface data in testing software Geomagic Qualify rapidly detect fighter joystick (CAD) model and product manufacturing differences, to assist the company to undertake high-end technology research and breakthrough.

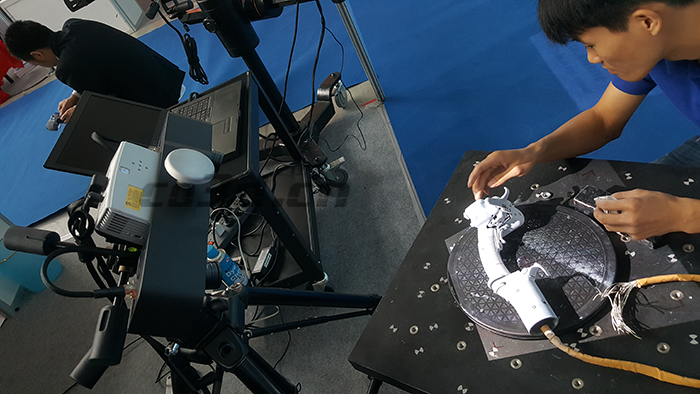

Preparatory work

Spray imaging agent: improve the surface background color contrast and obtain better scanning data.

Post marking point: to make the data obtained in scanning software to locate splicing.

Su27 fighter joystick scan chart

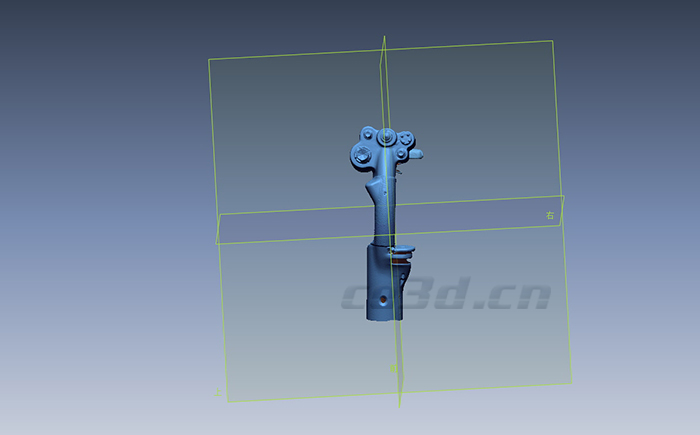

Su27 fighter joystick STL data graph

(Design X)

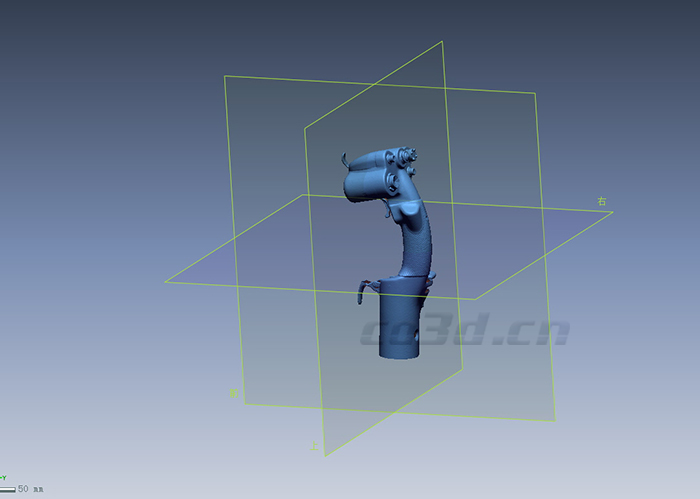

Su27 fighter joystick STL data graph

(Design X)