Three-dimensional inspection of aircraft blade workpieces

Aircraft blade is a special part, it is a large number, complex shape, high requirements, difficult processing, and is a frequent failure of parts has been the key to the production of engine factories, so the manpower, material resources, financial resources invested in it are relatively large, and domestic and foreign engine manufacturers are doing their best to improve the performance, production capacity and quality of blades to meet market needs.

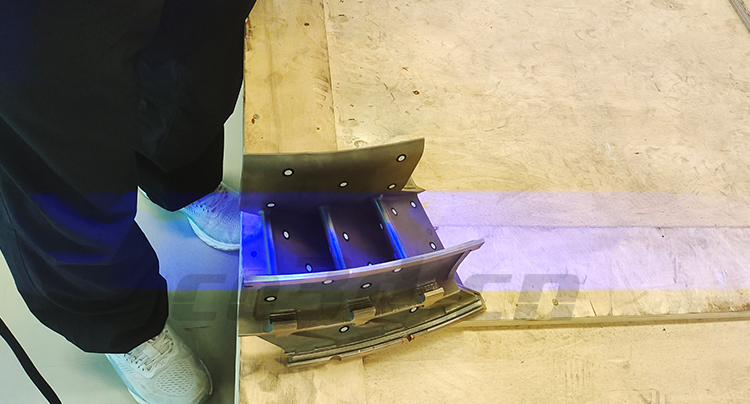

Actual diagram of aircraft blade workpiece

Pracical problems

1. The blade parts have thin walls, large twisted blade bodies, and complex profiles, which are easy to produce deformation, which seriously affects the processing accuracy and surface quality of the blades. How to strictly control the processing error of the blade and ensure good profile accuracy has become the focus of the inspection work.

2. The traditional detection method can not scientifically guide the production and processing of blades, the advanced technology is reflected in the improvement and innovation of blades, so that the level of blade manufacturing technology must be improved, and at the same time, the blade processing measurement is required to achieve digitalization, reflect its accuracy, and accurately give the actual value of each point of the blade and the error of the theoretical design of the blade.

Scan the site map

Scan the site map

Solutions

Hualang 3D technology engineers used the handheld 3D scanner HOLON B71 to scan to quickly obtain accurate 3D data of aircraft blades, with 2020000 points/s per second for rapid scanning and imaging. HOLON B71 3D Scanner has the advantages of strong applicability, wide application, fast detection and accurate results, which makes 3D scanners widely used in blade manufacturers.

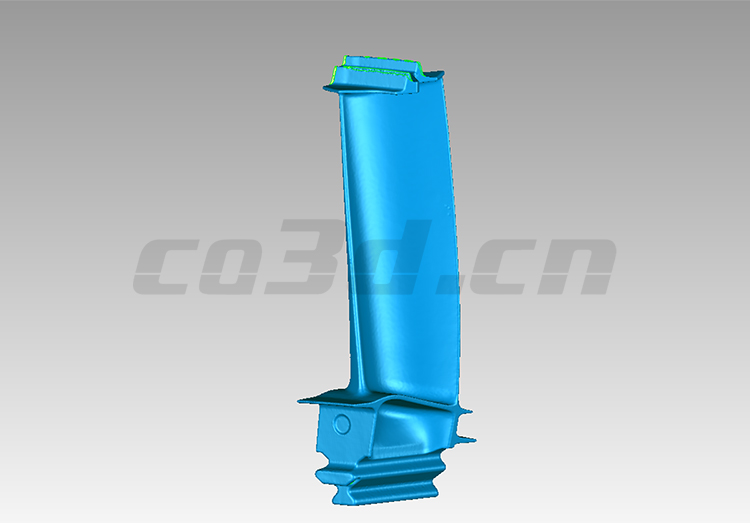

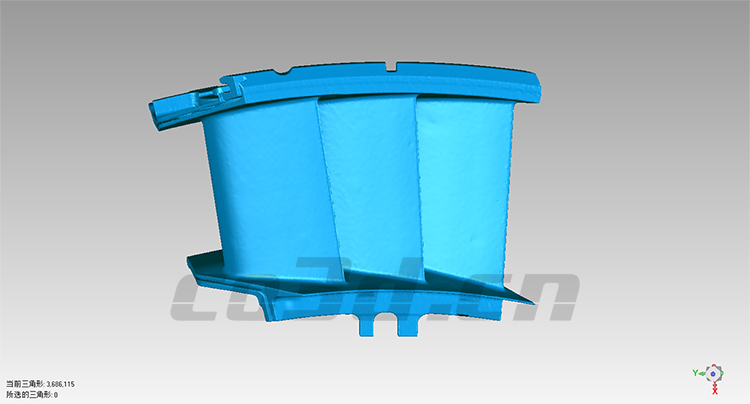

3D data of aircraft blades was obtained by fast scanning using the handheld 3D scanner HOLON B71. Imported 3D software for data optimization and successfully solved the customer's problem of measuring blades. Achieve the accuracy and effect of customer needs. It makes the customer's design and processing more convenient, and the research and development process faster.

STL data chart of aircraft blades

STL data chart of aircraft blades

STL data chart of aircraft blades