Fuel injection pump reverse scanning case

A well-known domestic fuel injection pump manufacturer hopes to quickly obtain the appearance data of the original fuel injection pump through the three-dimensional scanner and accelerate the development of new products.

Practical problems

1. The use of traditional measuring methods (such as gages, fixtures, three coordinates, etc.) is very cumbersome and time consuming, and it is not easy to accurately and quickly measure and detect the structure of the fuel injection pump.

2. The shape of the fuel injection pump is complex, and the grooves have different shapes and curved surfaces. The amount of 3D data acquired is incomplete and cannot be redesigned.

Co3d solutions

Fuel injection pumps are an important part of automotive diesel engines. Considered as the 'heart' component of a diesel engine, it can cause the entire diesel engine to malfunction if something goes wrong. The company hopes to use the 3D scanner to scan the fuel pump in three dimensions and carry out secondary design and improvement of the product. In response to customer needs, Huaguang 3D engineers proposed a solution to use: Huaguang 3D scanner 3DS + fast acquisition fuel injection pump high-precision 3D data import reverse design software (Geomagic Studio) to convert scanned data into triangular mesh surface data reuse Post-processing is carried out in mainstream design software such as Pro/E and UG to speed up the secondary design of the fuel injection pump.

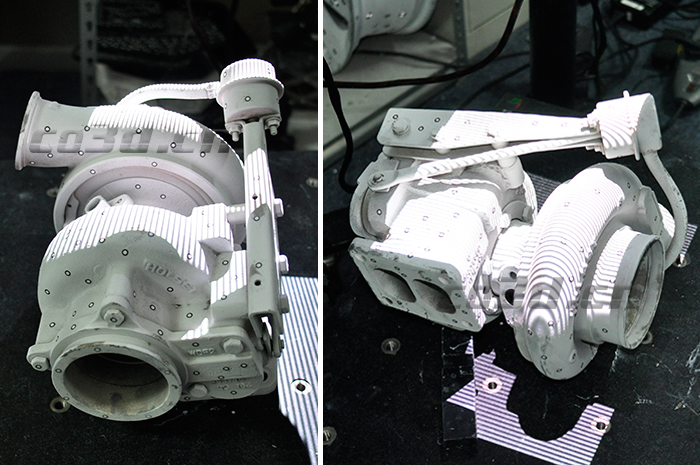

Fuel injection pump scanning site

1. Preparations in the early stage

Spraying the developer: Improve the background color contrast of the sample surface for better scan data.

Paste mark points: The acquired data is positioned and stitched in the scanning software.

Fuel injection pump scanning site

2, 3D scanning

Huaguang 3D scanner (3DS+) scans fast, and it takes only 10 minutes to obtain 3D data of fuel injection pump, and the data precision is up to 0.02mm. Huaguang 3D scanner (3DS+) adopts extrapolation multi-frequency phase shift grating technology, code point calibration technology and fully automatic splicing technology. The fuel injection pump data is imported into the three-dimensional reverse software (Geomagic) for processing, and the processed data is imported into mainstream design software such as Pro/E and UG to carry out reverse design of the engine. Accelerate the development of new products and improve engine performance.

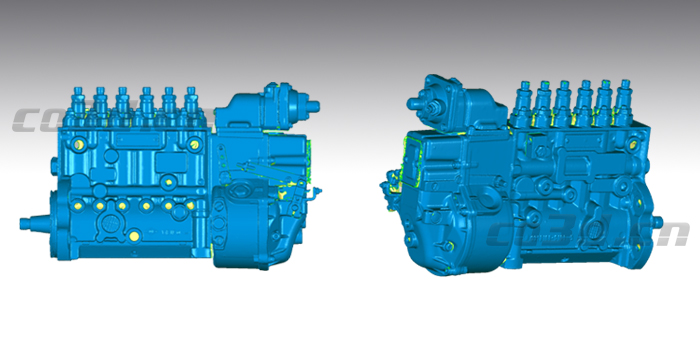

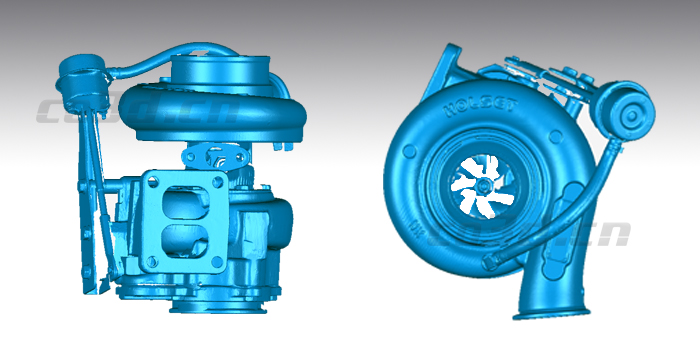

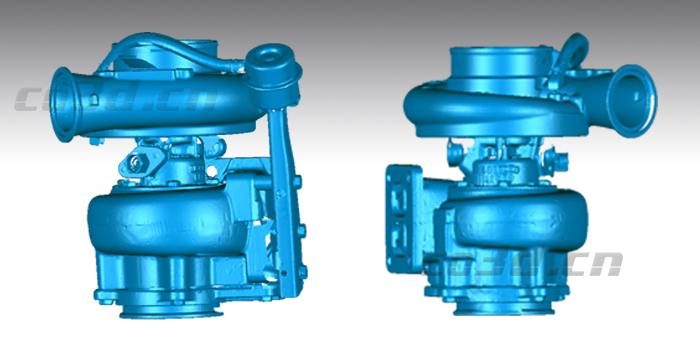

Fuel injection pump three-dimensional scanning STL data

Fuel injection pump three-dimensional scanning STL data

Fuel injection pump three-dimensional scanning STL data