Hockey stick 3D scanning case

A hockey stick manufacturer in Guangdong has a very high arc design requirement. It is difficult for designers to design. In order to speed up the production efficiency of the hockey stick, the company hopes to use the 3D scanner to quickly scan the 3D model of the hockey stick. , reverse design.

Practical problems

Due to the complicated surface of the hockey stick surface, the design cycle is long and the efficiency is low, which requires high accuracy for three-dimensional data.

Co3d solutions

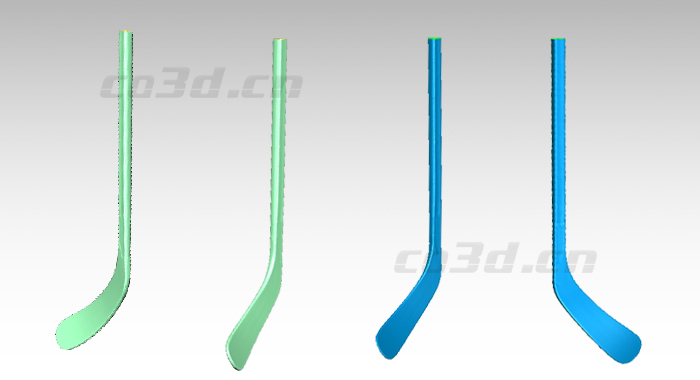

Product samples → Data acquisition → Data processing CAD system → Model reconstruction → Manufacturing system → New products.

Hockey stick 3D scanning

Hockey stick 3D scanning

Hockey stick 3D scanning

The company requires three-dimensional scanning of the hockey stick using a camera-type 3D scanner. The scanned three-dimensional data of the hockey stick will affect the secondary design in the later stage, and the required scanning accuracy is high. Huaguang 3D technical engineer uses 3D scanner 3DX to scan the car's 3D data and carry out the reverse design of the hockey stick. Huaguang 3D scanner 3DX has high scanning efficiency and can quickly acquire the 3D data of the hockey stick. The data precision is high. The data intelligent stitching scanning precision can reach 0.01~0.03mm, and the multiple data stitching precision is high, without layering and striping.

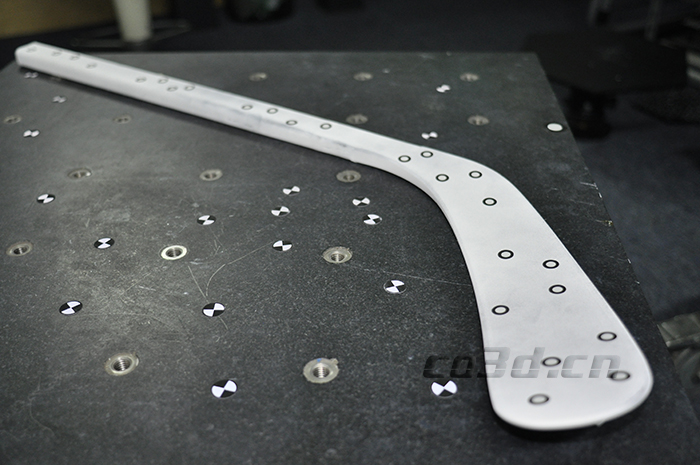

1. Preparations in the early stage

Spraying the developer: Improve the background color contrast of the sample surface, and the 3D scanner can better obtain the 3D scan data of the hockey stick.

Paste mark points: The acquired 3D scan data is positioned and stitched in the scanning software.

Hockey stick physical map

2, 3D scanning

After spraying the developer and pasting the marker points, the 3D scanner 3DX can quickly acquire the 3D data of the hockey stick in just 7 minutes, and the comprehensive scanning accuracy is ±0.01mm. The scanned hockey stick 3D scan data is imported into 3D reverse software (Geomagic) for processing, and the processed hockey stick STL data is imported into Pro/E, UG and other mainstream design software to perform secondary design of the hockey stick. To meet customer needs.

Hockey stick scan pre-work