3D scanning measurement of the volume of the wine cylinder

It is often said that 'Ginger is old and spicy, and wine is Chen's fragrance'. If you want to have good wine, you must have a good wine storage container, that is, the wine tank. The use of wine storage in the wine tank is conducive to moisture penetration, evaporation, and accelerated aging, making the wine more mellow. Therefore, since ancient times, there has been a choice of wine storage.

Wine cell site scan

The production and production of the wine tank is a complicated process, from soil screening to coloring. The middle is the selection of materials, the production of the model, the burning of the stove, the final washing and finishing, and each step requires manual effort to complete. If there is a loophole in the next step, the subsequent steps will not be carried out or the quality of the product will not be affected, which will affect the quality and taste of the wine, and cause significant losses to the production. The wine tank is made of ceramics and is a fragile product. Some collisions may occur during transportation, which may cause cracking problems. After the wine is loaded, there will be a phenomenon of water leakage. A tank manufacturer needs to measure the volume of the tank, get accurate shape data, make some steps to improve and improve efficiency.

Practical problems

The tank itself is very large and taller than the height of the person. It is an overall measurement. The shape is similar to an ellipse. The upper layer is larger than the lower layer, the arc is large, the surface is smooth, and it is easy to reflect. It has certain difficulty in measurement. There are some obstacles in the work of using traditional scanners. It is inconvenient to use and requires a lot of manpower assistance. The scanned data is incomplete and inaccurate, and the desired effect is not obtained. Still using a hand-held 3D scanner is simple, fast, saves time, saves material and improves work efficiency.

Co3d soiutions

Equipment used: HOLON760 handheld 3D scanner

Hand-held design, easy to carry, ready to use, improve work efficiency, can measure large objects without the use of photogrammetry system, great convenience for large tank scanning; dual industrial camera, automatic stitching technology and independent research and development Scanning software with ultra-high scanning accuracy and working efficiency, scanning from different angles and positions, large-area can also be quickly scanned; real-time visual, side-by-side operation, and timely filling of defects according to the omission of operation, no need to post Rescan again to save time. Obtain 3D data maps for comparison testing to improve production efficiency and control quality issues.

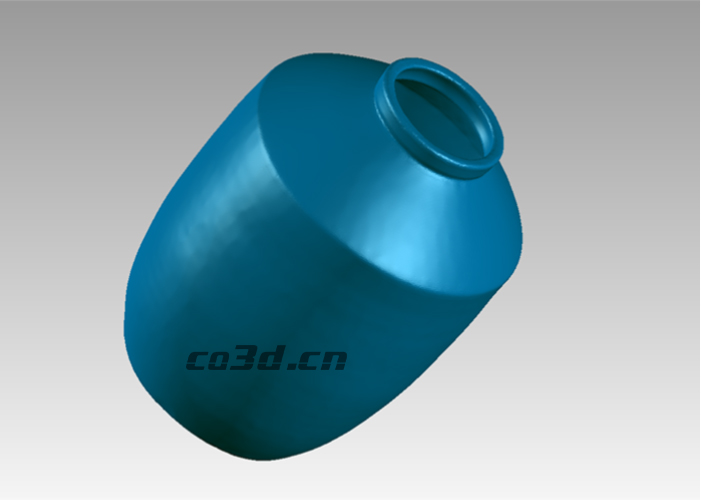

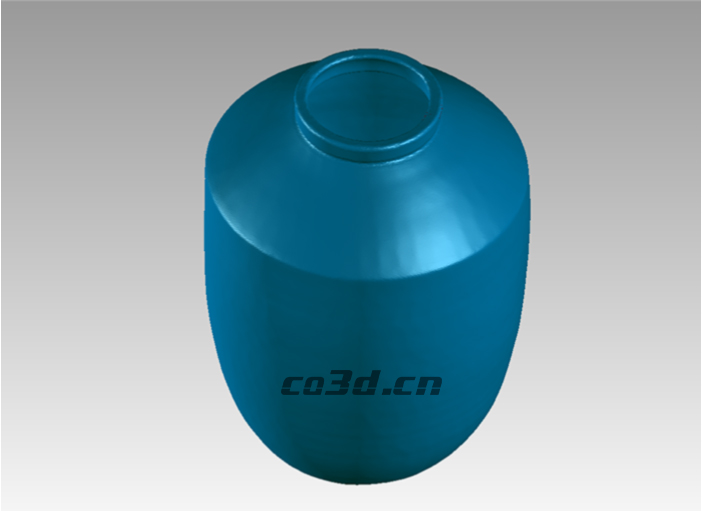

Wine tank STL data chart

Wine tank STL data chart

Wine tank STL data chart