Mold three-dimensional inspection

China is gradually moving from a mold manufacturing country to a mold manufacturing power. As far as the domestic market is concerned, the production and demand of the mold industry are booming, the investment enthusiasm of enterprises is rising, and large technological transformation projects and new construction projects are constantly appearing. For foreign markets, China's mold industry has performed equally well. The mold industry is actively exploring emerging markets while the traditional market is steadily advancing, and even marginal markets that have been neglected in the past have been developed.

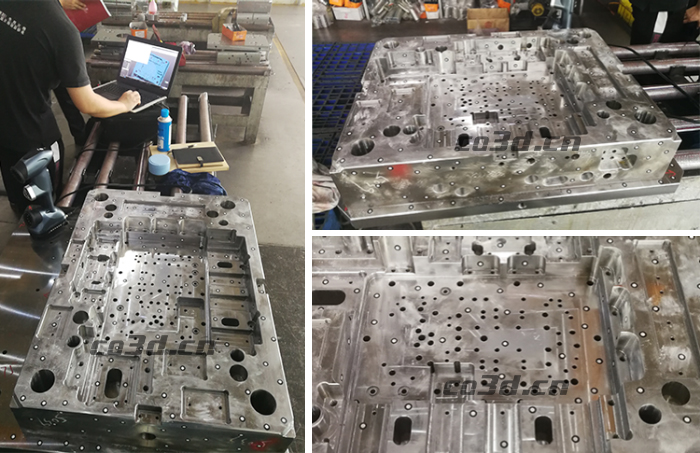

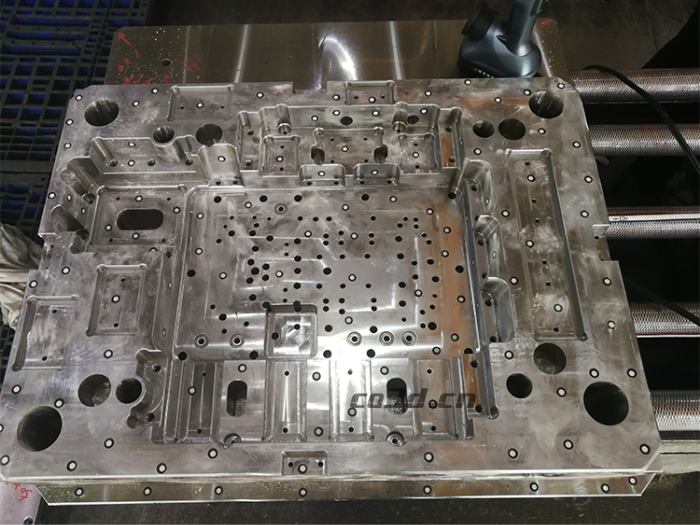

Mold scanning scene map

Simply put, a mold is a tool used to make a shaped article. The tool consists of various parts. Different molds are composed of different parts. The physical shape of the formed material is used to realize the processing of the shape of the object. The tool that makes the blank a part of a particular shape and size. The development level of mold production is one of the important signs of the level of mechanical manufacturing. After a long time of use, the mold is prone to wear and tear, and maintenance is required. In terms of structural design and process, it is also necessary to continuously improve and improve. In this aspect, the data can be obtained by using a 3D scanner.

Mold scanning scene map

Practical problems

The mold is a precision tool with a complex shape that withstands the expansion of the billet and is highly desirable in all aspects. Each mold has its own specific contour and shape.

The molds that customers need to scan are large, bulky, and difficult to move. The surface shape is complex and uneven, with many holes and small and deep holes.

The scanner equipment is very demanding. If you use the traditional scanner, it will be very difficult for the scanning work. The scanned data is not complete and the precision is not high enough to be completed. ,

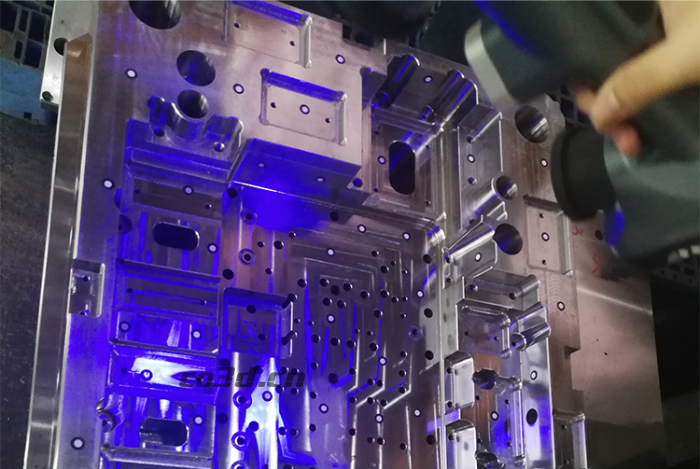

Mold scanning scene map

Co3d solutions

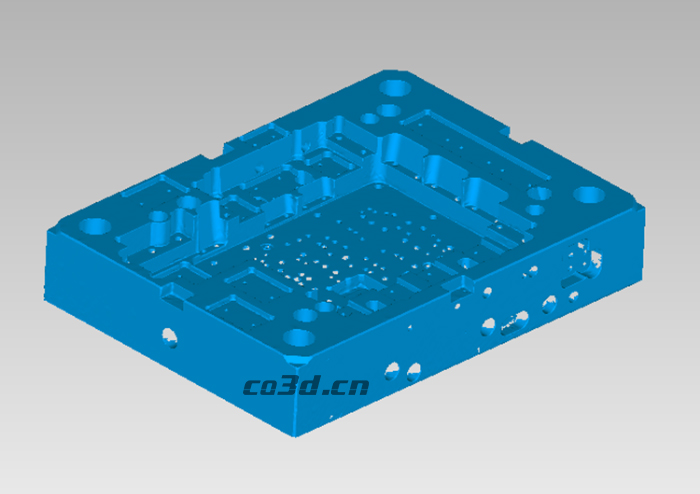

After understanding the customer's scanning artifacts and requirements, we decided to use our handheld 3D scanner HOLON760. The operation process is flexible and convenient for complex workpieces. The HOLON760 light source is composed of 7 sets of crossed laser lines plus an additional laser line for a total of 15 laser lines, which makes the scanning speed faster, higher precision and more stable. It can also be switched to a single laser scanning mode for deep holes. Or it is difficult to scan the dead angle scan to measure the data with high precision, fast measurement and scanning speed, greatly improve work efficiency, new independent research and development technology, and high technical level. Automatic splicing from different angles is scanned, and data is imported into 3D inspection software for detection and analysis. ,

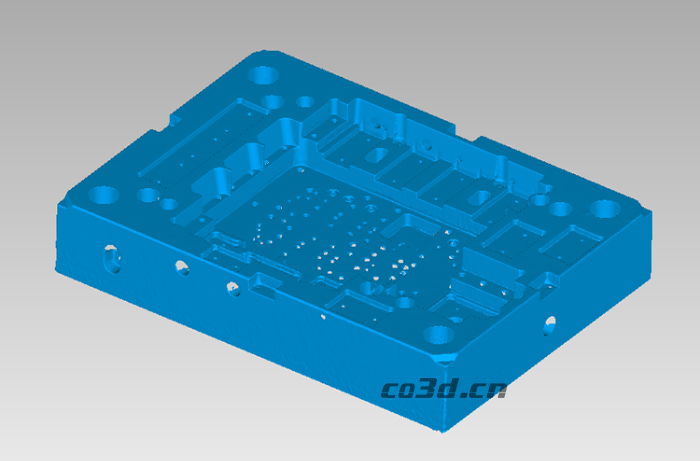

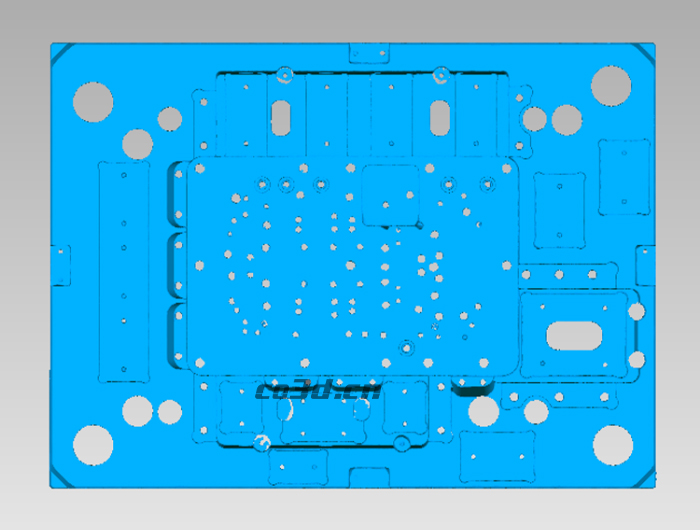

Mold STL data chart

Mold STL data chart

Mold STL data chart