Mold three-dimensional scanning

The mold has a specific contour or cavity shape. It needs to withstand the expansion force of the blank during production. It has high requirements on structural strength, stiffness, surface hardness, surface roughness and processing accuracy. The mold company determines product positioning and market positioning according to the market. In order to ensure the quality of the mold manufacturing, reduce the production cost, it is necessary to improve the quality of the mold design and shorten the mold design cycle.

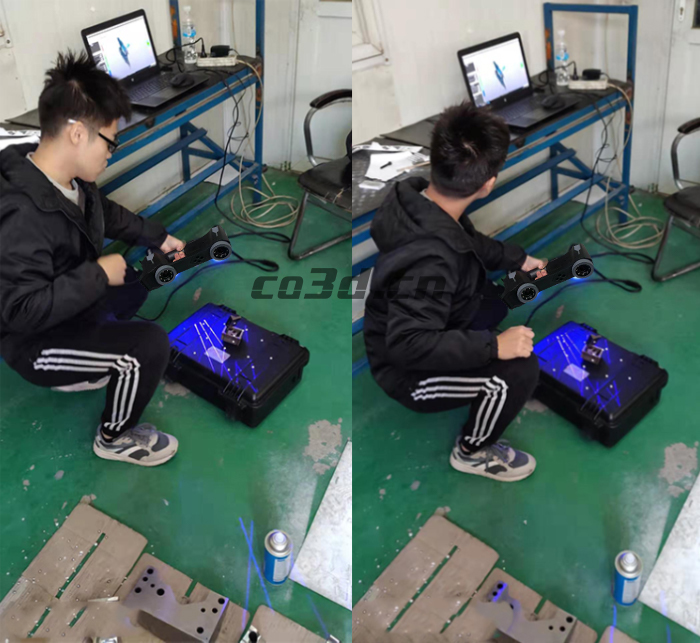

Mold site scan

Practical problems

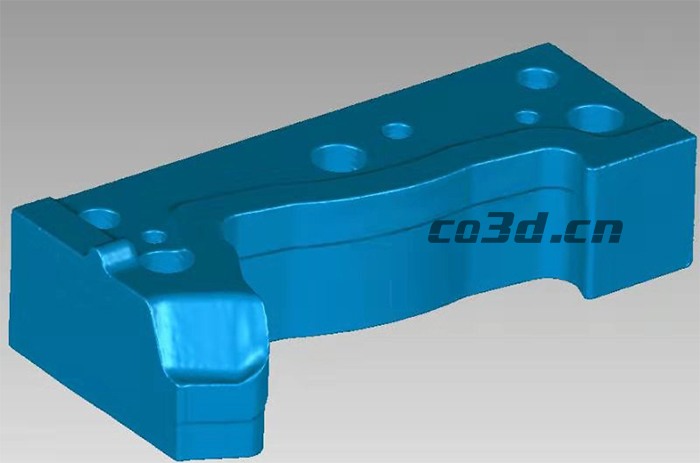

Molds are precision tools and the shape is generally more complicated. The mold scanned for the customer has a complex surface with holes, and the hole is deep due to the thicker mold. There are protruding cylindrical components.

When scanning with a conventional scanner, only the outline is displayed, but the hole depth cannot be scanned accurately, and the inside cannot be captured, which cannot satisfy the customer's needs. Customers find our company and want to use advanced 3D scanners to get solutions.

Mold site scan

Co3d solutions

Our engineers use the hand-held 3D scanner HOLON380 to scan according to the characteristics of the customer's workpiece. Using 3 sets of cross-laser lines plus 1 additional laser line, a total of 7 laser lines scan the overall contour of the mold, switching to a single laser scanning mode, special scanning Deep hole position for precise capture of the hole. It is easy to operate and can be visualized in real time. The scanned data is imported into the 3D software for processing. The data has high precision, the processing details are satisfactory to the customer, the analysis report is easy to understand, the customer can intuitively understand the product needs to improve the problem, and it is very beneficial for the place to be used later, so the customer Very satisfied with our equipment.

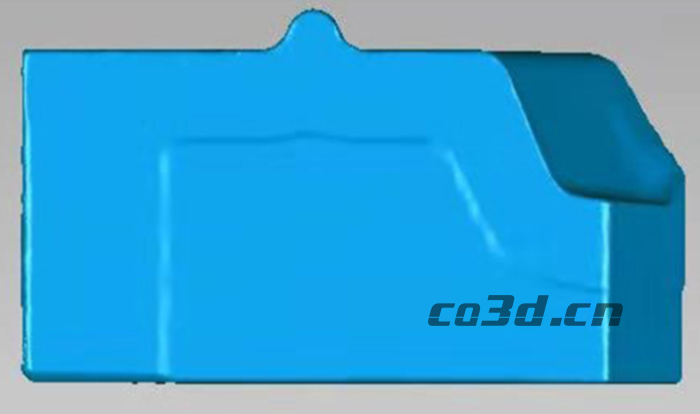

Mold STL data chart

Mold STL data chart

Mold STL data chart