Three-dimensional inspection of circuit boards

The circuit board is the most active industry in the contemporary electronic components industry, and its industry growth rate is generally higher than the electronic component industry by about 3 percentage points. The 11th Five-Year Plan for China's national economic and social development proposes to upgrade the electronic information manufacturing industry. The circuit board industry will maintain rapid growth, and demand upgrading and industrial transfer are the basic driving forces for the development of the industry. Customers should also upgrade their boards based on development, and make design improvements to enhance service life and manufacturing technology.

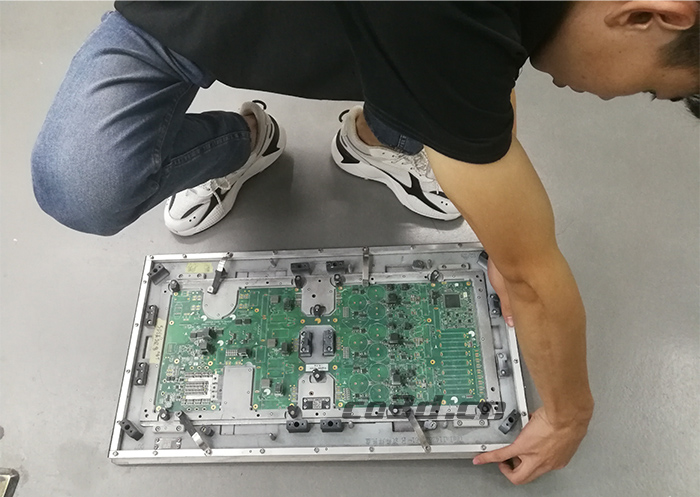

Circuit board real shot

Practical problems

There are many types of circuit boards, and different boards are not the same. However, the components of the board are many, reflecting different functions. Therefore, the surface structure of the circuit board is very complicated, uneven and dense, and many parts are difficult to scan. When trying to use a conventional scanner, the scanned data does not accurately scan out the small parts, and the obtained data cannot be used in later use. It is now scanned again using an advanced 3D scanner.

Circuit board search ah second scene map

Co3d solutions

In response to customer requirements and claims, our company uses the handheld 3D scanner HOLON751 for scanning, using blue laser line scanning, which makes scanning faster, higher precision, more stable, greatly improving work efficiency, and new independent research and development technology. Guaranteed. Carefully scan the corners of the corner for precise capture. This device is extremely portable and small, and does not take up space. Easy to operate, easy to use, there will be special training. It can be used regardless of environmental influences, workpiece structure and user capabilities.

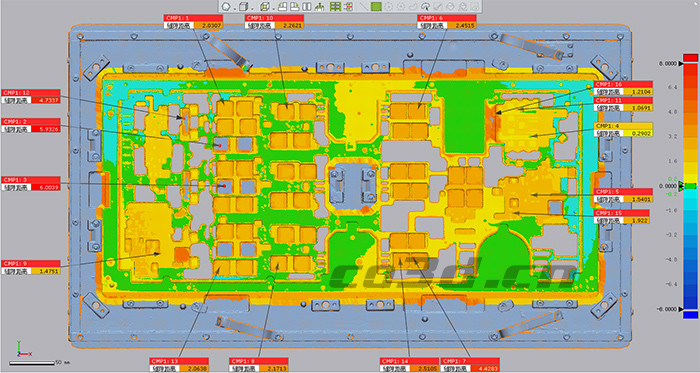

The scanned data is highly accurate and imported into 3D software for analysis. In the whole scanning process, the scanning speed is fast, the data acquisition accuracy is high, the scanning effect in the details is very good, the analysis report is easy to understand, the time is short, the customer feels very satisfied, and the equipment is greatly recognized.

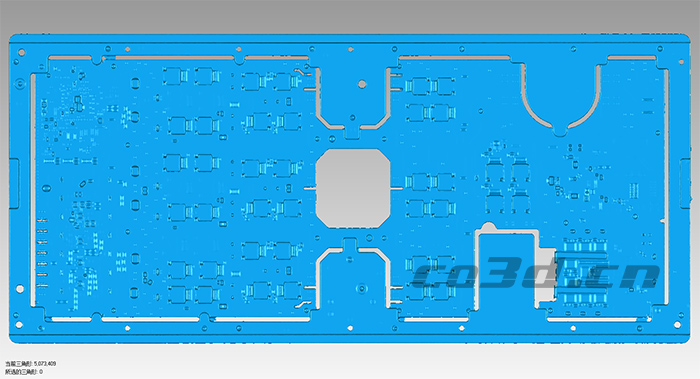

Circuit board STL data chart

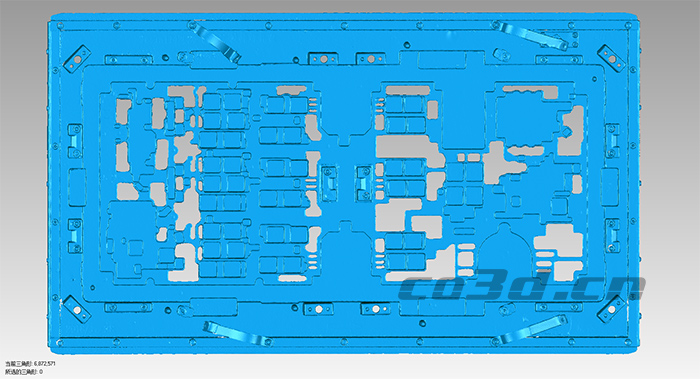

Circuit board STL data chart

Circuit board three-dimensional data map