Mold is a tool used to make molding products. In industrial production, it is used for injection molding, blow molding, extrusion, die casting or forging, smelting, stamping and other ways to get the required products. The mold is easy to break, bend and gnaw in the process of use. It is necessary to record the damage in detail to provide information for finding and solving problems. So we need to use 3D scanning technology to detect and find the problem.

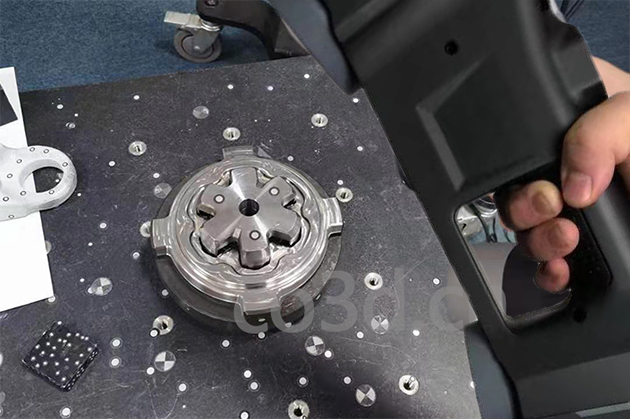

On site scanning of mould

Practical problems

The process of the workpiece is complex, and there are some details such as grooves, curved surfaces, holes and so on, which are difficult to detect manually. In addition, the object is a combination, and some details cannot be measured manually. It means that the quality can not be controlled, there may be deviations. Using 3D scanner can measure all the details without touching through laser line scanning, which provides a simple and convenient detection scheme.

On site scanning of mould

CO3D solution

Co3d engineers use the hand-held 3D scanner holon751 to complete the scanning of this object. The first is to put a marker on the object. Holon751 has standard mode and fine mode. First, the standard mode is used to scan the whole workpiece to obtain data, and then the fine mode is used to scan the small parts. Different scanning modes are used in different parts to obtain high-precision scanning data.

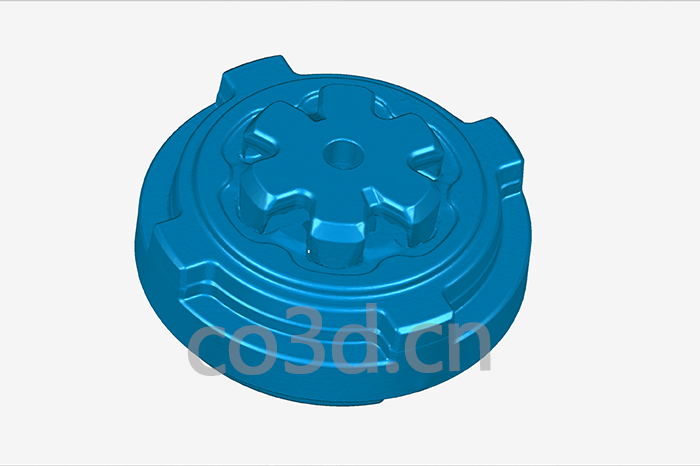

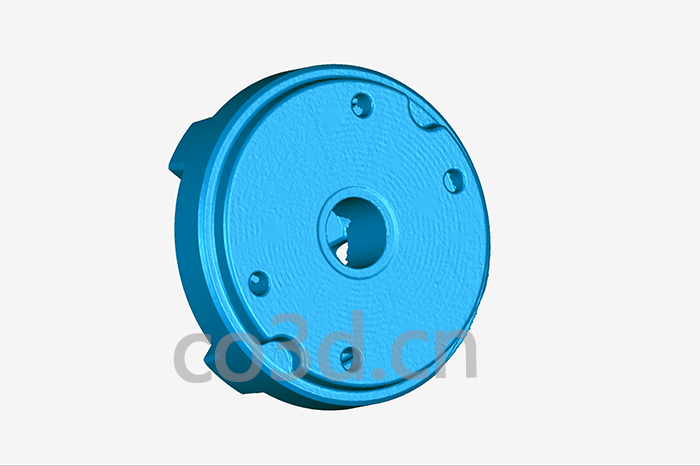

STL data chart of mold scanning

STL data chart of mold scanning

The acquired data is imported into the 3D testing software, and the testing comparison can generate a simple and easy to understand analysis and testing report. In order to help customers find problems, to control the quality of products and solve problems.

STL data chart of mold scanning