3D scanning case of plastic parts

Plastic parts is an abbreviation for combined molds used for compression molding, extrusion molding, injection molding, blow molding and low foam molding. Through coordinated changes, a series of plastic parts of different shapes and sizes can be processed. In the process of plasticizing and strengthening, it is prone to deformation and inaccurate installation hole positions, which will have an impact on the later installation work.

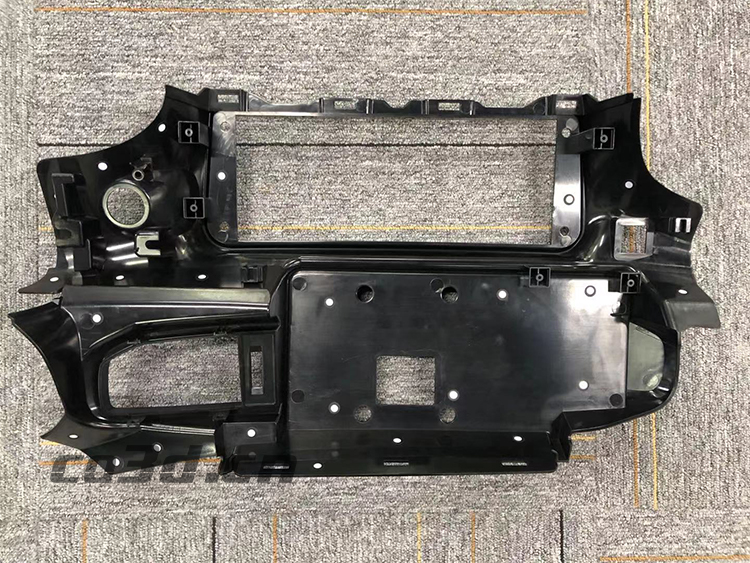

On-site entity map

Practical problem

Plastic parts have complex shapes, many components, and detailed holes are not easy to scan. Using traditional three-coordinate scanning equipment, the scanning time is long, and the scanning of fine parts is not complete, which easily leads to low data accuracy. In recent years, handheld 3D scanners have become the choice of many customers as a high-precision, fast-efficiency, non-contact, and portable 3D scanning device.

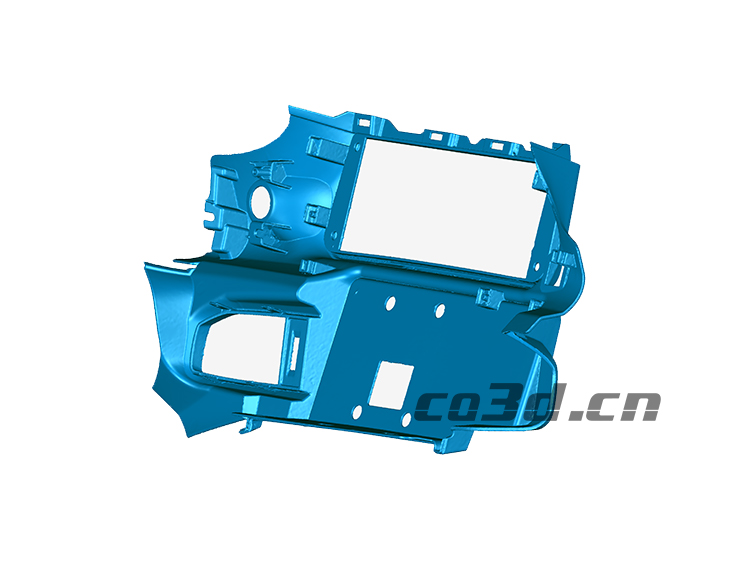

STL data graph

CO3D solutions

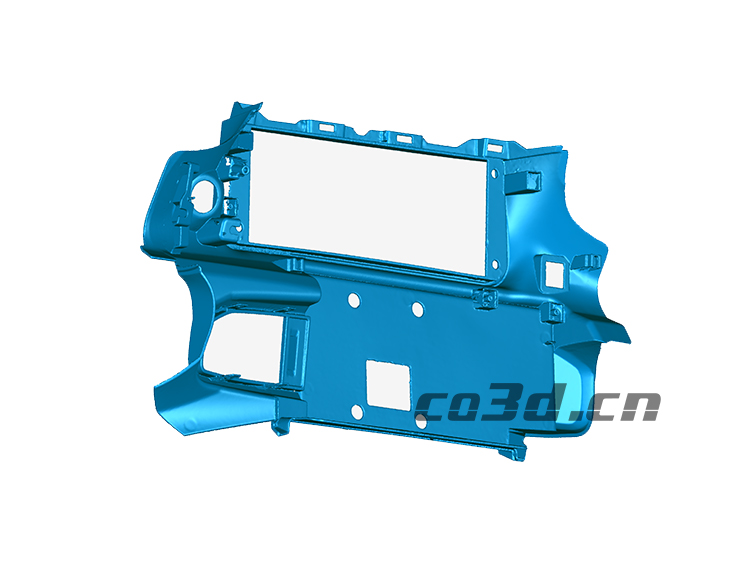

Use HOLON 3D handheld 3D scanner HOLON751, the equipment has fine mode and scanning deep hole mode. It can scan the small parts of the customer's workpiece with high precision, as well as deep hole single-line scanning. Quickly collect high-precision three-dimensional data of plastic parts through a three-dimensional scanner. Import the data into the 3D software for comparison and analysis of the original digital and analog, so as to obtain the problem report of the data

STL data graph