3D scanning of sand castings

Steel, iron, and most non-ferrous alloy castings can be obtained by sand casting method. Due to the low cost and easy availability of molding materials used in sand casting, the mold manufacturing is simple, and can adapt to single piece production, batch production, and mass production of castings. For a long time, it has been a basic process in casting production.

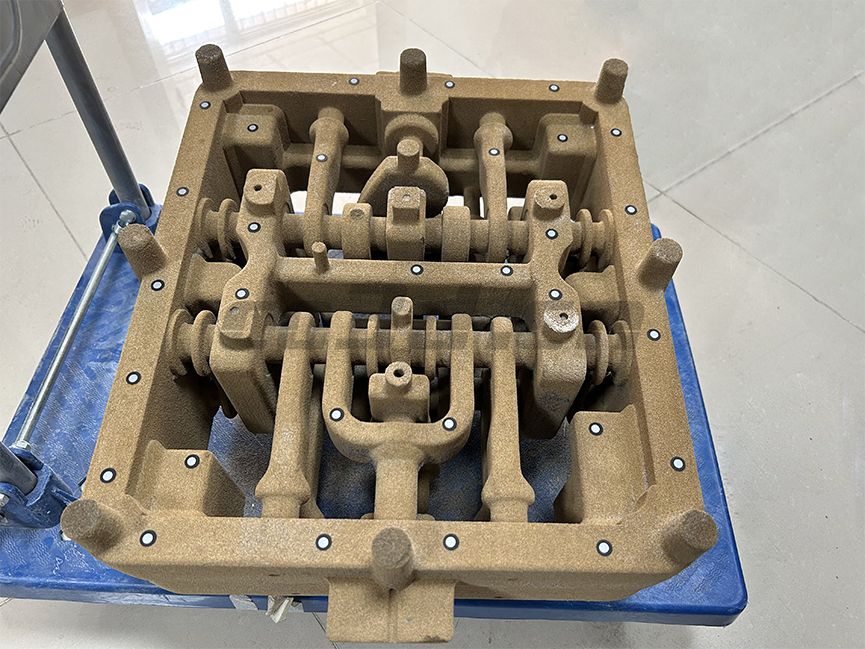

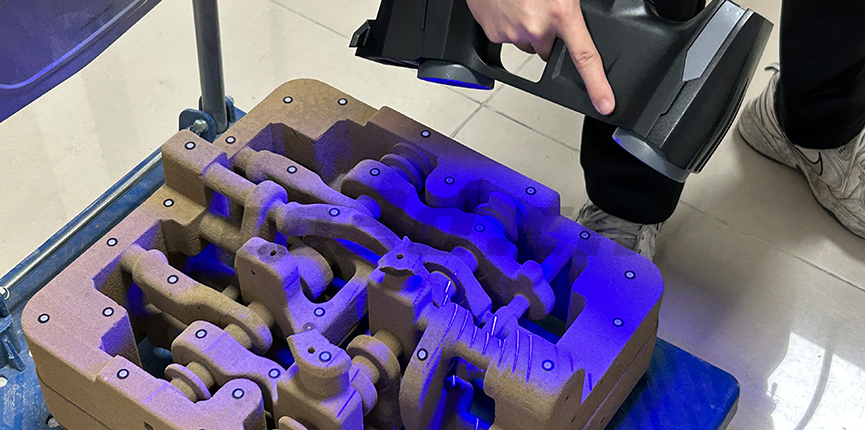

Physical Drawing of Sand Casting

Pracical problems

In order to ensure that the sand mold and core produced have a certain strength and do not deform or damage during transportation, molding, and pouring of liquid metal, it is generally necessary to add sand binder in the casting to bond the loose sand particles into sand. It is very difficult to detect using traditional techniques.

Physical Drawing of Sand Casting

Solutions

3D scanning technology can be used for reverse and detection of sand castings, and for error detection after subsequent processing of sand castings. For detection of sand castings with high accuracy, Hollon handheld 3D scanner HOLON A22 is used to scan the 3D data of sand castings, with an accuracy of up to 0.02mm. It can be directly imported into the comparison detection software for error comparison analysis. This simple, convenient and high-precision detection method, Greatly improving the drawbacks of traditional testing methods and accelerating the rapid development of the casting industry.

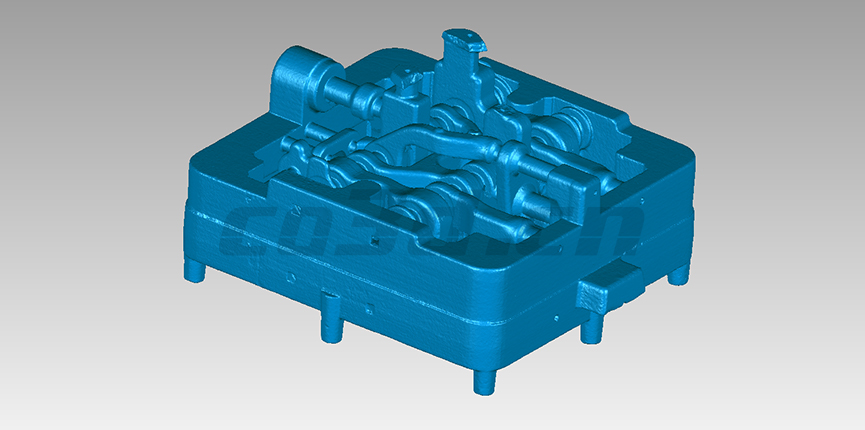

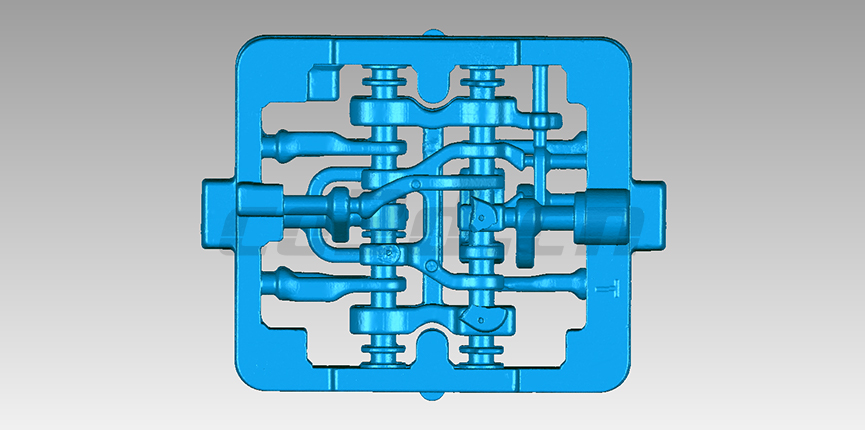

STL data chart for sand castings

STL data chart for sand castings