3D inspection of turbine blades

A hydraulic turbine is a power machine that converts the energy of water flow into rotating mechanical energy. It is a turbomachinery in fluid machinery and is used to drive a generator to generate electricity. The accuracy of the turbine blade profile is an important factor that affects the efficiency, output, cavitation and operating life of the turbine, and is an important indicator of the manufacturing level of the turbine.

Site scan

Practical problems

The blades of the hydraulic turbine are relatively large, and the unreasonable design of the water outlet edge of the blades will adversely affect the unit, so the data collection accuracy of the blades should be high. And the scanning time is short, and the acquired data can be accurately detected and analyzed. The current detection methods are time-consuming and labor-intensive, and cannot be accurately analyzed.

Site scan

Co3d solution

Using 3D photogrammetry with a 3D scanner can reduce the cumulative error of 3D scanning data splicing when scanning large workpieces for 3D measurement. The scanning speed is fast and the data accuracy is high.

First, three-dimensional photogrammetry is used to shoot images from different angles, and the 3D coordinates of the center of each code point are obtained through software calculations. Then use a 3D scanner to quickly scan and obtain high-precision data. Import the data into the 3D inspection software for comparative analysis, which can generate simple and easy-to-understand inspection and analysis reports. In this way, it is possible to compare and understand the existing problems of the blades, modify and adjust, and avoid affecting the operation of the turbine.

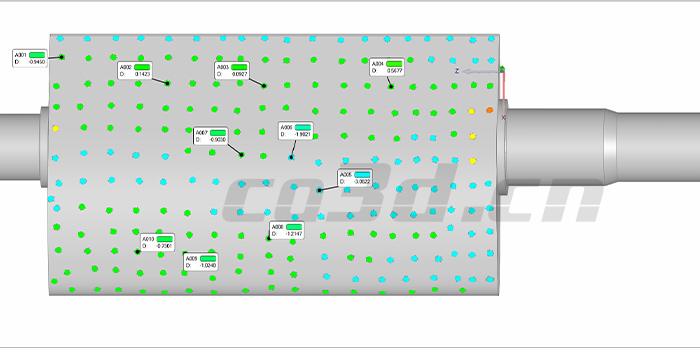

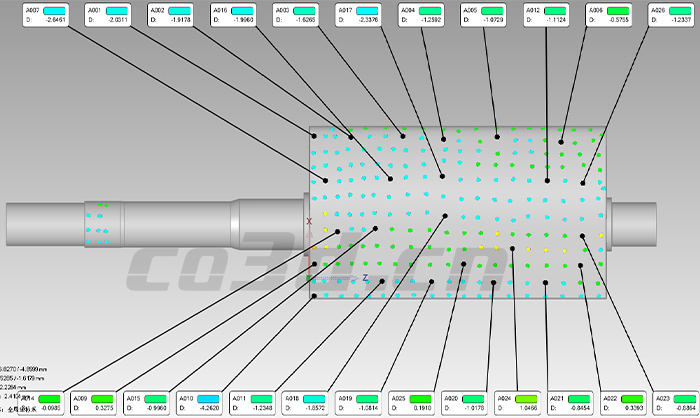

Detection analysis chart

Detection analysis chart