3D scanning of car dashboard

The customer is an automotive manufacturing enterprise that integrates research, development, production, and sales. They need to conduct testing and comparative analysis on the instrument panel, and traditional measurement methods cannot quickly and comprehensively obtain data. In order to meet market demand and improve enterprise competitiveness, customers have decided to abandon traditional measurement methods and introduce new scanning and comparison methods. It is learned that HOLON 3D is the first handheld 3D scanner manufacturer in China, which can quickly and accurately obtain data, comprehensively compare and analyze whether products are qualified, and improve product quality and detection efficiency.

Pracical problems

1. The surface of the product is black, with many curved surfaces, large radians, complex hole positions, and many included angles. It is not suitable to spray imaging agents, which increases the difficulty of scanning.

2. In addition to improving detection efficiency and rapid analysis, measurement accuracy should also be controlled, requiring global measurement accuracy to be controlled within 0.02mm.

Scan on-site image of car dashboard

Scan on-site image of car dashboard

Solutions

Based on the problems faced by customers, HOLON 3D quickly summarizes feasible solutions based on past experience. Stick marker points on the scanned sample to facilitate fixed point splicing. The HOLON 3D handheld 3D scanner HOLON B71 is used to scan the sample quickly and comprehensively. The scanning speed is extremely fast and the measurement accuracy is high. And it can be visualized in real time, and the part being scanned can be seen on the computer screen, making it convenient and practical to fill in any gaps.

Scan to obtain high-precision data, import 3D data into 3D software for processing, analyze the data, check whether the dashboard is qualified or where the problems exist. The detailed scanning processing effect is good, improving product quality and testing efficiency, and providing reference data for later product development.

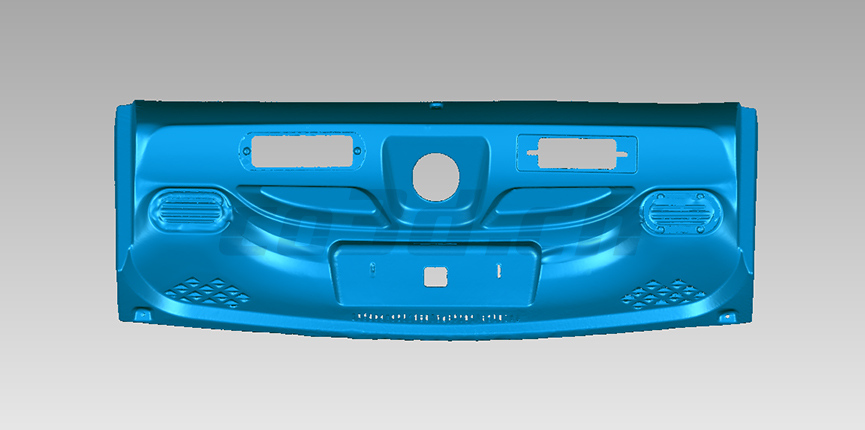

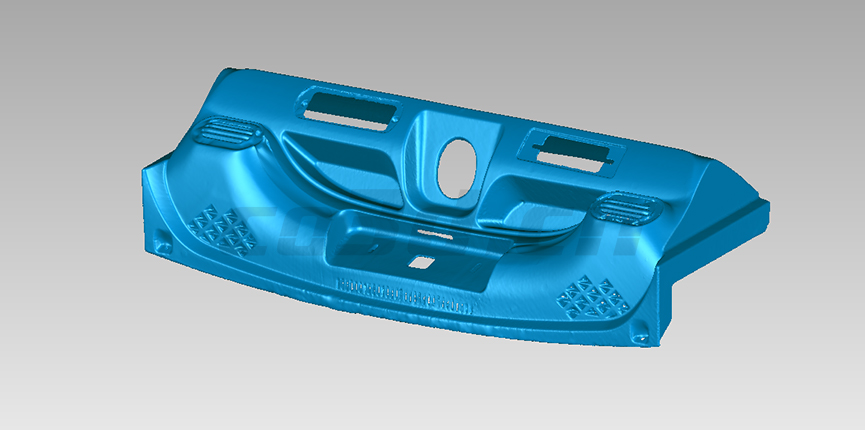

Car instrument panel STL data graph

Car instrument panel STL data graph