The automotive industry in China has developed rapidly in recent years and will continue to steadily develop in the future. As an important component of automobiles, car seats have a large demand for seats, so there is still huge development space for the passenger car seat industry in the future. A well-known manufacturer needs to perform a 3D scan of the seats.

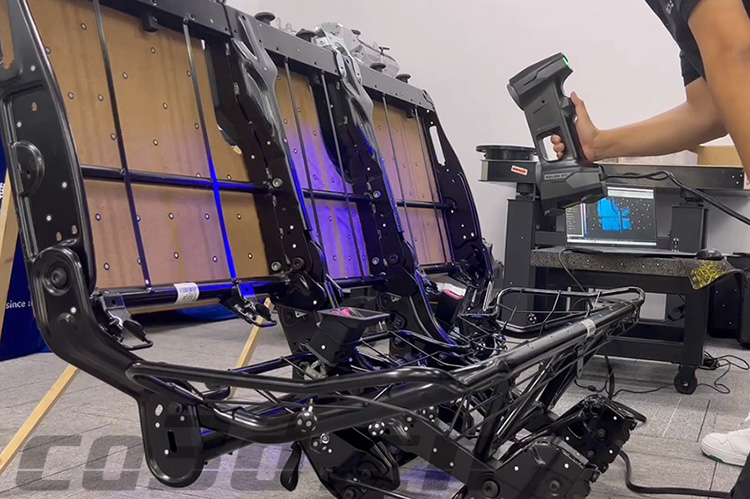

Product physical image

Practical problems

Product quality inspection requires high measurement accuracy. The workpiece has a black and dark surface, and the overall contour is complex, with many curved surfaces and included angles. Traditional measurement methods cannot accurately and comprehensively measure surface 3D data, and there is a lack of effective measurement solutions for complex contours and narrow dead corners.

Scan on-site images

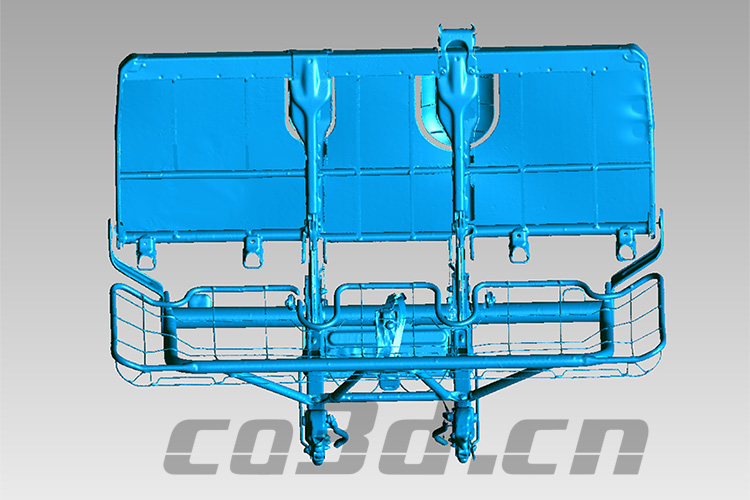

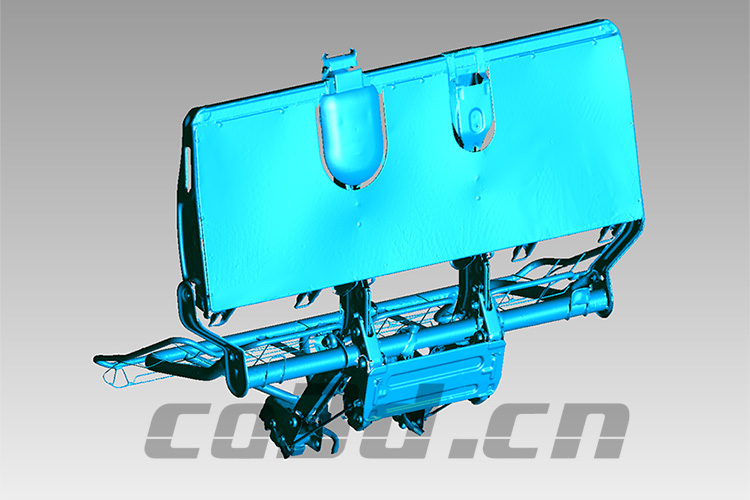

Co3d solution

According to the challenges faced, Hualang 3D engineers use a handheld HOLON B71 scanning system with strong adaptability to environmental light and surface sensitivity of the workpiece. The surface does not need to be sprayed with color difference agents, and the precision mode accuracy can reach 0.01mm. Multiple blue line lasers are used, and the scanning speed is fast. The 3D data obtained from scanning is imported into the detection software, and compared and analyzed with the original digital model to quickly obtain the detection report, which can greatly improve the efficiency of workpiece detection.

Car Seat STL Data Chart

Car Seat STL Data Chart

Car Seat STL Data Chart